Nylon for 3D Printing Impact-Resistant Alternative to the Plastics ABS or PA6

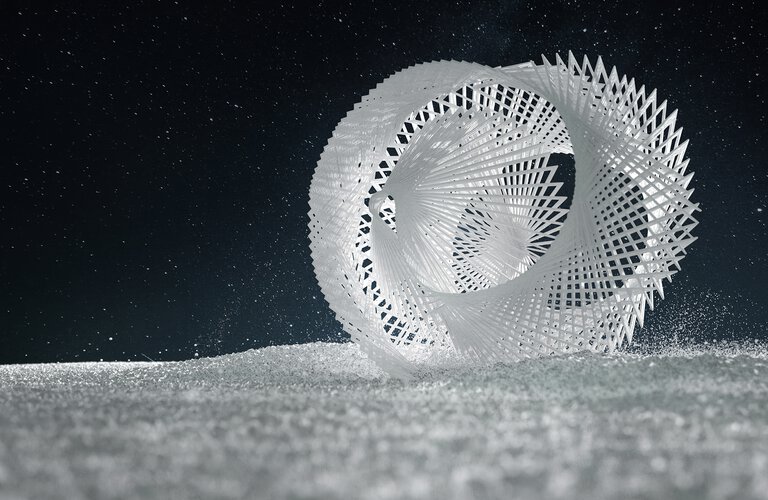

The high-performance plastic polyamide 11 (PA 11) is made from 100% renewable castor beans. PA 11, also known as nylon, is chemically and mechanically heat-resistant and is ideally suited for highly technical applications thanks to its durability. EOS materials of this class are an efficient, impact-resistant alternative to the plastics ABS or PA6, which have proven their value in injection molding. The additively manufactured end products are just as strong, flexible and durable as molded parts.

Fields of application

This material is ideally suited for producing functional elements that require high material strength (e.g. living hinges) and/or impact resistance. Therefore, components for which fragmentation is inadmissible (e.g. in the interior of vehicles) are among the typical fields of application.

PA 1101 ClimateNeutral Polyamide 11, white

The white, light-transmissive, additively manufactured parts are characterized by high impact resistance and elongation at break. They do not splinter even under the highest mechanical loads. Compared to PA 12, they have higher temperature resistance and nearly constant mechanical properties over a wide temperature range.

100% proven quality and 0% CO2e

PA 11 is a bio-based material (castor oil) with a smaller carbon footprint than petrol-based polymers. Following our purpose Responsible Manufacturing, we have implemented optimizations in the PA 1101 ClimateNeutral production process to reduce its carbon footprint. In addition, we invest in Gold Standard climate protection projects to offset the unavoidable greenhouse gas emissions. The carbon-neutral material comes with proven quality and material composition. Customers will receive a certificate that verifies the correct calculation and offsetting for the application.

The material is also available as PA 1101 without carbon offsetting.

Typical mechanical properties

| Tensile modulus | 1600 MPa |

| Tensile strength | 48 MPa |

| Elongation at break | 45% |

Thermal properties

| Melting temperature (20°C/min) | 201°C |

| Heat deflection temperature (1.80 MPa) | 46°C |

| Heat deflection temperature (0.65 MPa) | 180°C |

Physical properties

| Density | 990 kg/m³ |

Material processed by

PA 1102 Black Polyamide 11, black

Parts made from the mass-dyed polyamide 11 powder have a uniform black color and are therefore particularly suitable for visible areas that are subject to abrasive wear. In addition, they have high impact resistance and elongation at break and do not splinter even under the highest levels of mechanical stress. Compared to PA 12, they have higher temperature resistance and nearly constant mechanical properties over a wide temperature range. The material PA 1102 black is based on renewable resources (castor oil).

Typical mechanical properties

| Tensile modulus | 1560 MPa XY / 1610 MPa Z |

| Tensile strength | 48 MPa |

| Elongation at break | 45% XY / 28% Z |

Thermal properties

| Melting temperature (20°C/min) | 201°C |

| Heat deflection temperature (1.80 MPa) | 46°C |

| Heat deflection temperature (0.45 MPa) | 180°C |

Physical properties

| Density | 990 kg/m³ |

Material processed by

HP 11-30 Polyamide 11, filled with carbon fibers

This high-performance plastic made from PA 11 features high strength combined with increased impact resistance and elongation at break due to being enforced with carbon fibers. Since the fibers are encapsulated (compounded) in the raw material, the dark gray components have comparable mechanical properties in all three spatial directions (isotropy). This material is electrostatically dissipative.

Typical mechanical properties

| Tensile modulus | 3300 MPa XY |

| Tensile strength | 56 MPa XY |

| Elongation at break | 8 - 9% |

Thermal properties

| Melting temperature (20°C/min) | 187°C ± 3°C |

Physical properties

| Density | 990 kg/m³ |

Material processed by

FR-106 Polyamide 11, flame-retardant

The white flame-retardant polyamide 11 is characterized by high ductility combined with excellent strength, making it particularly suitable for manufacturing components with complex geometries, such as housings and load-bearing connecting elements.

Typical mechanical properties

| Tensile modulus | 1392 MPa XY |

| Tensile strength | 46 MPa XY |

| Elongation at break | 38% Z |

Thermal properties

| Melting temperature (20°C/min) | 187°C ± 3°C |

| Heat deflection temperature (1.82 MPa) | 70°C |

| Heat deflection temperature (0.45 MPa) | 186°C |

Physical properties

| Density | 1070 kg/m³ |

Complies with standards: FAR 25.853; 60 sec. burn requirement

Material processed by