Different degrees of automation for individual requirements

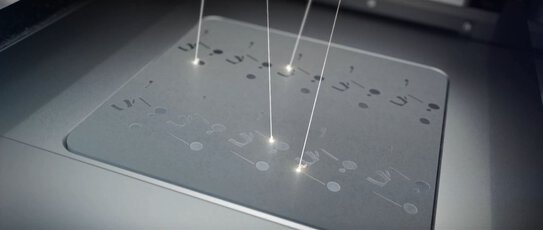

Consistent part quality over the entire build space

Up to four precision fiber lasers cover

the entire 300 x 300 mm area

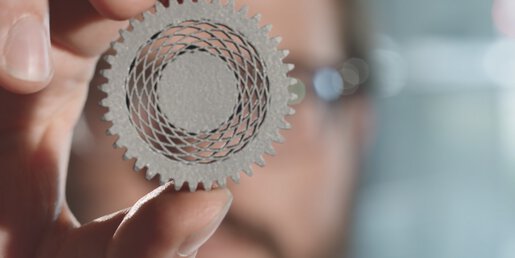

Success Story Industrialization of the Laser Powder Bed Fusion Process

Challenge:

Additive manufacturing with extensive automation in order to facilitate more comprehensive industrialization.

Solution:

Use of digitization in the overall process through the interfaces of the EOS M 300-4, incorporating the capacity of the multi-laser system.

Results:

- Digital: The OPC UA interface of EOSCONNECT Core facilitates connectivity to monitoring and business intelligence solutions

- Automated: Deep process and software integration form the basis for extensive industrialization

- Reliable: Few secondary processing times, and reproducible high part quality

Want to learn more? Get the free Success Story here.

Technical DataEOS M 300-4 |

Download Factsheet | pdf | 387,7 KB | |

| Construction Volume | 300 x 300 x 400mm (11.8 x 11.8 x 15.8 in) | |

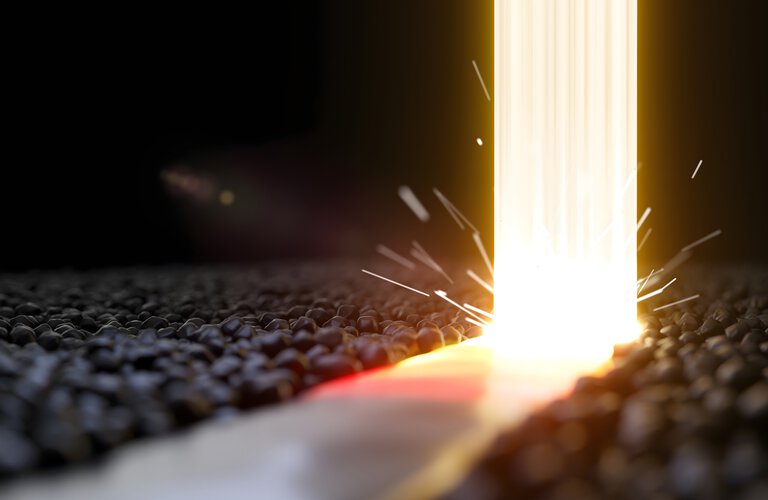

| Laser Type | Yb-fiber laser; 4 x 400 W | |

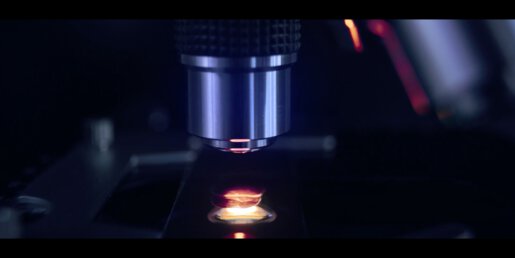

| Precision Optics | 4 F-theta-lenses; 4 high-speed scanners | |

| Scan Speed | up to 7.0 m/s (23 ft./sec) | |

| Focus Diameter | approx. 100 µm (0.004 in) | |

| Power Supply | 3 x 63 A | |

| Power Consumption | max. 19.6 kW / typical 16 kW | |

| compressed air supply | 7,000 hPa; 15 m³/h (102 psi; 530 ft³/h) | |

| Machine Dimensions (W x D x H) | 5,221 x 2,680 x 2,340 mm (205.6 x 105.5 x 92.1 in) (with EOS Transfer Station M) | |

| Recommended Installation Space | min. 8,800 x 5,200 x 3,500 mm (346.5 x 204.7 x 137.8 in) | |

| Weight | approx. 5.500 kg | |

| Software | EOSPRINT 2, EOS ParameterEditor, EOSTATE Monitoring Suite, EOSCONNECT Core, EOSCONNECT Core, EOSCONNECT MachinePark, Materialise Magics Metal Package and modules. |

Metal Materials for the EOS M 300-4

EOS materials are specially developed for DMLS and undergo strict quality assurance.

more about metal materialsMaterial Management Metal Materials

The EOS powder handling portfolio offers a wide range of products for advancing and sieving metal powder. The products have different degrees of automation, are suited for small or large powder quantities and can be used flexibly and independently of the respective EOS metal system.

Software

EOS offers tried-and-tested software solutions for all process steps in additive manufacturing – from the preparation of CAD design data and job preparation to quality control.