DMLS Metal Materials for EOS 3D printer

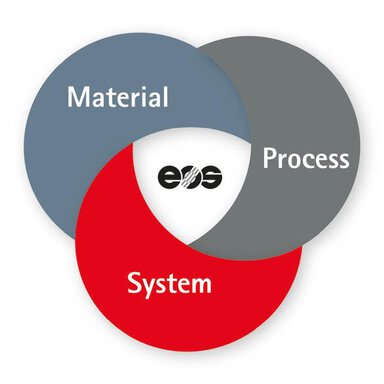

We at EOS offer an extensive portfolio of high tech materials designed specifically for metal 3D printing using our DMLS Technology. Our quality controlled material supply chain – from the source to delivery – ensures regulatory compliance, lot traceability, flexible volumes and fast delivery. All our materials, process parameters and metal 3D printer are optimally aligned to reliably and repeatably provide the desired part properties for production of your parts. We call this the EOS Quality Triangle which is unique to our DMLS-Technology, a proven powder bed fusion technology for metal additive manufacturing.

EOS’ portfolio currently encompasses over 20 alloys and over 70 validated processes for all our DMLS systems. The portfolio includes aluminium, cobalt chrome, nickel-based, refractory metal, stainless steels, tool steels and titanium alloys. These enable a multitude of applications to be additively manufactured in the desired part quality.

Our team of materials and metallurgy experts continuously develop the DMLS materials based on customer requirements and feedback. Our R&D teams are working on a wide range of future materials such as bronze, pure copper, metallic glasses, light weight alloys just to name a few.

Our Extensive Portfolio and 3D Printing Material Expertise Offer

Technology Readiness Level (TRL)

EOS offers the most comprehensive range of materials with over 20 alloys and over 70 validated processes for our systems. The portfolio includes aluminium, cobalt chrome, nickel alloys, refractory metal, stainless steels, tool steels and titanium.

Our R&D teams are working on a wide range of other materials such as bronze, pure copper, copper alloys, metallic glasses, light weight alloys and many more.

We have over 30 years of DMLS expertise regarding the combination and interdependencies between high quality metal powders, process parameters and system – EOS’ Quality Triangle – means more confidence that each AM part is built with integrity and that support can be provided for all industries and applications.

For more clarity and transparency, EOS has adapted the well-known Technology Readiness Levels (TRL) for 3D printing – again unique in the industry.

The TRLs have been consolidated into two product categories:

- Premium products offer highly validated data plus a high repeatability

- Core products are also tried and tested but, as they are less mature, come only with basic data

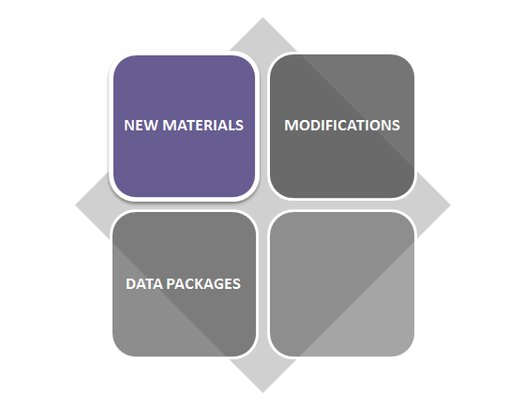

EOS Custom Materials and Services

Are you looking for a tailor-made material for your application? Or more data to ease qualification?

Beyond our extensive portfolio we also offer a solution that is tailored to your specific application and requirements. This can range from feasibility to full validation including all necessary post processing steps. The EOS’s Technology Readiness Levels (TRLs) offer the framework for the development.

- NEW MATERIALS: Do you have specific part properties in mind for your application and the material is open? Or need a material that is not in our portfolio? We can build a demo part to help you decide if the material and/or business case is right. If so, then we can develop a new material or process based on the requirements of your application.

- MODIFICATIONS: Do you need higher productivity? A specific surface quality? Modification of the recommended heat treatment procedure? We can modify existing process based on your needs.

- DATA PACKAGE: Do you need data to support integration of DMLS technology in your production? Or characterization of certain part properties? We can generate data for properties such as fatigue, corrosion, hardness, heat treatment, etc. Contact us so we can do suitable test plan together.