EOS Aluminum Powders for 3D Printing Applications

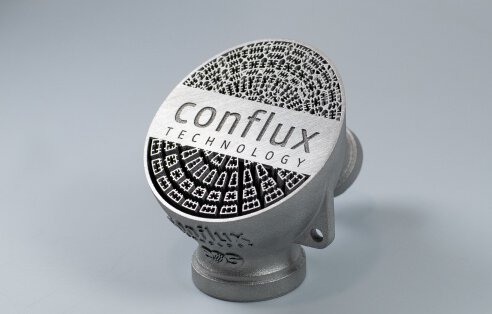

Aluminum’s material characteristics make it ideal for many applications in many industries, for example aerospace and automotive.

EOS’ aluminum family of powders encompasses the AlSi10Mg, AlF357 and Al2139 AM alloys which are typical aluminum-silicon casting alloys. These powders are designed and tested for use on EOS’ metal 3D printers.

All EOS aluminum powders are shipped with an inspection certificate (according to EN 10204, Type 3.1) showing the results of the extensive QA testing not only of the powder itself, but also of test parts built on a dedicated system with a dedicated process.

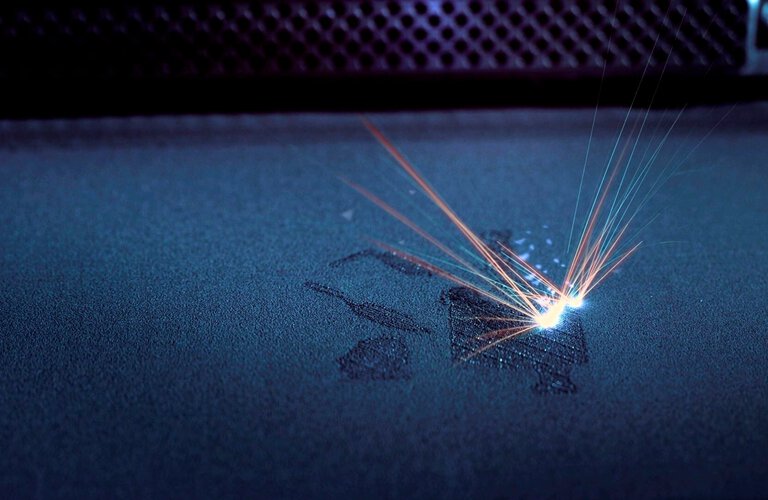

EOS also offers a wide range of validated processes for each of the above materials. These offer the optimal combination of parameters (e.g. laser power, layer thickness, etc.) in order to ensure that the properties of the 3D printed part are consistently achieved.

EOS Aluminum Al5X1

EOS Aluminum Al5X1 is a heat-treatable aluminum alloy designed for AM to offer a compelling combination of high strength and high elongation. The recommended single-step heat treatment does not require a water quench and enables robust part production.

| Typical Part Properties | |

| Chemical composition in compliance with | Designed for AM |

| Ultimate Tensile Strength | 410 MPa |

| Yield Strength | 380 MPa |

| Elongation @ Break | 14 % |

EOS Aluminum AlSi10Mg

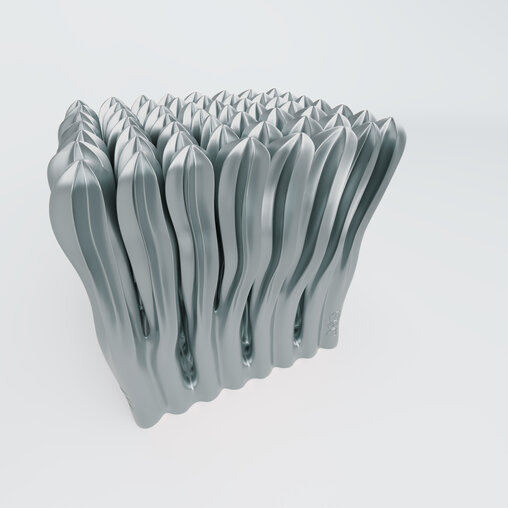

Parts printed using EOS Aluminum AlSi10Mg offer good strength, hardness and dynamic properties as well as good thermal properties and low weight.

| Typical Part Properties | |

| Chemical composition in compliance with | AlSi10Mg |

| Ultimate Tensile Strength | 460 MPa |

| Yield Strength | 245 MPa |

| Elongation @ Break | 5 % |

EOS Aluminum AlF357

Parts printed using EOS Aluminum AlF357 offer a combination of low weight, corrosion resistance and high dynamic load bearing capacity.

| Typical Part Properties | |

| Chemical composition in compliance with | AlSi7Mg0.6, SAE AMS 4289 |

| Ultimate Tensile Strength | 330 MPa |

| Yield Strength | 260 MPa |

| Elongation @ Break | 11 % |

EOS Aluminum Al2139 AM

EOS Aluminum Al2139 AM is a 2000-series high strength alloy specifically designed for AM. It demonstrates outstanding performance in elevated temperatures up to 200 °C. The fast and simple heat

treatment procedure enables an affordable part production.

| Typical Part Properties(T4 heat treated state) | |

| Chemical composition | modified from Aluminum Association Teal Sheet for Al2139 |

| Ultimate Tensile Strength | 520 MPa |

| Yield Strength | 460 MPa |

| Elongation @ Break | 4 % |