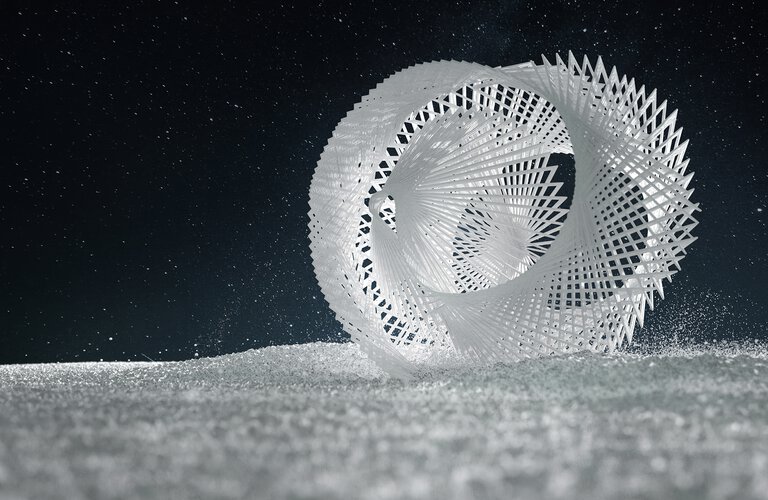

EOS Polyamide 12 Powders for 3D Printing

White polyamide 12 powder, also known as nylon, is the most tested material for additive manufacturing on the market. Parts made from nylon are robust, stable for long periods of time, chemically resistant and extremely versatile. EOS materials based on polyamide 12 are a high-performance alternative to plastics like ABS or PA6 that have proven their value in injection molding. The additively manufactured end products are just as strong, flexible and durable as molded parts.

Fields of application:

This cost-efficient general-purpose material is suitable for a variety of applications, including functional prototypes and qualified series production parts from the industry.

PA 2200 CarbonReduced Polyamide 12, white

The property profile of durable white parts made from PA 2200 is very balanced: such parts are characterized by strength, rigidity and good chemical resistance. They can be biocompatible and certified for contact with foodstuffs.

100% proven quality and 45% less CO2e

The petrol-based polymer PA 2200 CarbonReduced has an elevated impact on climate. Following our purpose Responsible Manufacturing, we are constantly increasing the production efficiency of this material. Due to the use of renewable energies, the carbon footprint is almost 45% lower. This has no influence on its high quality and material composition.

Together with Fraunhofer EMI, we have carried out a life cycle analysis (LCA) on PA 2200 CarbonReduced. This gives our customers with transparency on the climate footprint.

The material is also available as PA 2200 with a higher carbon impact.

| Typical mechanical properties | |

| Tensile modulus | 1650 MPa |

| Tensile strength | 48 MPa |

| Elongation at break | 18% |

| Thermal properties | |

| Melting temperature (20°C/min) | 176°C |

| Heat deflection temperature (1.80 MPa) | 70°C |

| Heat deflection temperature (0.65 MPa) | 154°C |

| Physical properties | |

| Density | 930 kg/m³ |

Material processed by

PA 2201 Polyamide 12, natural

Parts made from pigment free polyamide 12 powder are also white but appear slightly more transparent. This material can be approved for contact with food and its other properties are similar to PA 2200 – strength, rigidity and good chemical resistance.

| Typical mechanical properties | |

| Tensile modulus | 1700 MPa |

| Tensile strength | 48 MPa |

| Elongation at break | 15% |

| Thermal properties | |

| Melting temperature (20°C/min) | 176°C |

| Heat deflection temperature (1.80 MPa) | 70°C |

| Heat deflection temperature (0.45 MPa) | 154°C |

| Physical properties | |

| Density | 930 kg/m³ |

Material processed by

PrimePart FR (PA 2241 FR) Polyamide 12, flame-retardant

This polyamide-12-based material is white and contains a halogen flame retardant. Thanks to its good refreshability, it is very cost-efficient compared to other flame-retardant materials. The additively manufactured parts are elastic with good tensile strength and are used in the interior of aircraft, e.g. ventilation ducts and exhaust valves.

| Typical mechanical properties | |

| Tensile modulus | 1900 MPa |

| Tensile strength | 49 MPa XY / 46 MPa Z |

| Elongation at break | 9% Z |

| Thermal properties | |

| Melting temperature (20°C/min) | 185°C |

| Heat deflection temperature (1.80 MPa) | 84°C |

| Heat deflection temperature (0.45 MPa) | 154°C |

| Physical properties | |

| Density | 1000 kg/m³ |

Complies with standards and qualifications: FAR 25.853, AIRBUS directive for AM manufactured plastic parts.

Material processed by

PA 2210 FR Polyamide, flame-retardant

This white polyamide 12 powder is equipped with a halogen-free chemical flame retardant. Underwriters Laboratories (UL) has issued a Blue Card (equivalent to the well-known Yellow Card) specifically dedicated to 3D printing materials to PA 2210 FR: at wall thicknesses above 3 mm, it meets the required fire protection class UL 94 / V-0, primarily relevant for the production of electric and electronic components and applications in the aerospace and automotive sectors.

| Typical mechanical properties | |

| Tensile modulus | 2500 MPa XY / 2300 MPa Z |

| Tensile strength | 46 MPa XY / 41 MPa Z |

| Elongation at break | 4% |

| Thermal properties | |

| Melting temperature (20°C/min) | 185°C |

| Heat deflection temperature (1.80 MPa) | 84°C |

| Heat deflection temperature (0.45 MPa) | 154°C |

| Physical properties | |

| Density | 1060 kg/m³ |

PA 3200 GF Polyamide 12, filled with glass beads

Parts made from this white polyamide 12 powder filled with glass beads have high rigidity and good elongation at break. They are also especially resistant to wear and tear, and thermally resilient. This material is used mostly in vehicle engines and molding material for deep-drawing tools.

| Typical mechanical properties | |

| Tensile modulus | 3200 MPa |

| Tensile strength | 51 MPa |

| Elongation at break | 9% |

| Thermal properties | |

| Melting temperature (20°C/min) | 185°C |

| Heat deflection temperature (1.80 MPa) | 96°C |

| Heat deflection temperature (0.45 MPa) | 179°C |

| Physical properties | |

| Density | 1200 kg/m³ |

Material processed by

Alumide® Polyamide 12, filled with aluminum

This metallic gray, aluminum-filled polyamide 12 powder is characterized by high rigidity, a metallic appearance and a range of useful post-processing options. The surfaces of Alumide parts can very easily be finished by grinding, polishing or coating. The chip-breaking effect of the aluminum filling simplifies machining. Another impressive property of Alumide® is its very high temperature resistance, which results in excellent dimensional stability at high temperatures. Parts made from Alumide® can therefore be used in functional applications at high temperatures.

| Typical mechanical properties | |

| Tensile modulus | 3800 MPa |

| Tensile strength | 48 MPa |

| Elongation at break | 4% Z |

| Thermal properties | |

| Melting temperature (20°C/min) | 176°C |

| Heat deflection temperature (1.80 MPa) | 144°C |

| Heat deflection temperature (0.45 MPa) | 175°C |

| Physical properties | |

| Density | 1360 kg/m³ |

Material processed by

PA 640-GSL Polyamide 12, filled with glass beads and carbon fibers

This dark gray PA 12 material is filled with both hollow glass beads and carbon fibers. This makes it exceptionally temperature-resistant and rigid, but also very light.

| Typical mechanical properties | |

| Tensile modulus | 3816 MPa XY / 1945 MPa Z |

| Tensile strength | 49 MPa XY / 33 MPa Z |

| Elongation at break | 3% |

| Thermal properties | |

| Melting temperature (20°C/min) | 185°C |

| Heat deflection temperature (1.82 MPa) | 170°C |

| Heat deflection temperature (0.45 MPa) | 180°C |

| Physical properties | |

| Density | 820 kg/m³ |

Material processed by