Stay Ahead of the Game: 3D Printing Benefits

Additive manufacturing is becoming increasingly popular due to the many benefits of 3D printing. But what exactly are the 3D printing advantages and how can they improve your business? Are there downsides as well? Read more about the pros and cons of additive manufacturing and what our customers have experienced with EOS technology.

Product Innovations Made Possible by Industrial 3D Printing

3D Printing Benefits: 6 Business Boosters

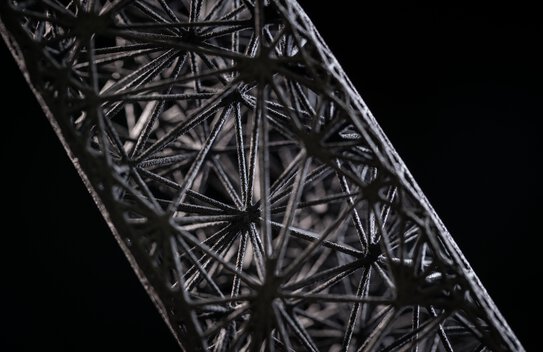

1 | Lightweight Design

In times of increasing raw material consumption - and thus also rising prices worldwide - it is of great importance to develop and produce products in a way that conserves resources as much as possible.

EOS 3D printing technology makes it possible to design and manufacture high-strength lightweight structures. These can be designed and built in a completely different and thus resource-saving way, so that they are significantly lighter than components from conventional production. This is a decisive advantage, especially for satellite or aircraft parts.

In addition, a lot of material is also saved during production, since - unlike subtractive manufacturing processes such as milling or turning - it is only applied where it is functionally necessary.

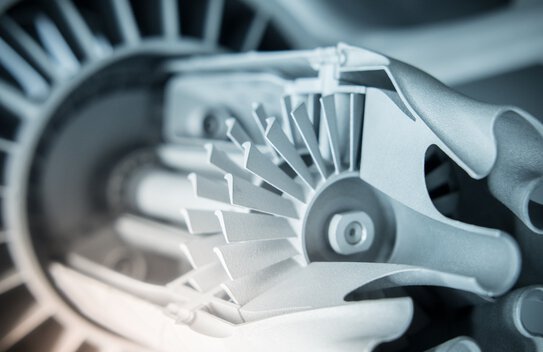

2 | Complex Geometries

Producing complex geometries, such as three-dimensional structures with undercuts or cavities, is generally not possible with traditional technologies such as milling, turning or casting, or only at disproportionately high costs.

In industrial 3D printing, the component is no longer determined by the manufacturing process, but solely by the desired design and functionality. Any shape that can be designed in a 3D CAD program can be created in 3D printers, as material is only applied where it is needed. Maximum design freedom goes hand in hand with lower material consumption - a win-win situation for any industry.

3 | Efficient Supply Chains

The economic benefits of 3D printing can be seen in supply chain and design optimization: lower inventory costs through on-demand printing; lower material and freight costs through lightweighting strategies; lower assembly, labor and tooling costs; shorter time-to-market; easier product customization; and advantageous high-mix, low-volume production - the list of savings opportunities is long. In addition, suppliers in many industries must guarantee spare parts availability of 10 years or longer. This requires extensive warehousing with high costs. On-demand printing of spare parts offers a lot of savings potential.

How high the ROI (return on investment) is and when a 3D printer amortizes itself depends on the individual circumstances in your company. We’re happy to advise you!

4 | Printing On Demand

Manufacturers are under pressure from various requirements and market demands. In some industries, such as automotive, consumer goods and medical, one of these demands is the customer's desire and need for customized products. Producing these profitably is a challenge, especially in terms of mass customization.

Production on demand with additive manufacturing technology from EOS enables manufacturing tailored to the respective batch, which places hardly any limits on product individualization.

5 | Functional Integration

For many applications, a compact, space-saving design with the same functionality is desirable. Fewer assembly parts mean lower assembly costs, reduced susceptibility to errors and more favorable logistics costs. There are numerous examples that show how EOS tool-less additive manufacturing can produce all the parts needed in one step.

Areas of application include joints, chain links, stabilized springs or scissor mechanisms in automation and production technology, but functional integration also plays an important role in medical technology and in the production of orthoses and prostheses.

6 | Sustainability

Responsible manufacturing plays a major role at EOS. 3D printing technology offers many opportunities for sustainable production:

3D printing is an enabler technology for sustainable end products, made possible by the advanced EOS technology and the complex geometries it enables. With 3D printing, only what is actually needed is printed. There is little production waste, no molds or special tools that need to be made. Additive manufacturing can also significantly reduce spare parts inventory. On-site, on-demand 3D printing can also have a positive impact on global supply chains. More environmentally friendly powders are in development - and EOS has created a closed-loop return program reusing used plastics.

Challenges of 3D Printing Technology

For all the 3D printing benefits, there are also challenges that we are working on: Through continuous improving of our material portfolio. Through different build chambers to better meet our customers' needs. Through thoughtful end-to-end solutions from design to 3D printing to post-processing.

If you have any questions or special requests, we are always happy to talk

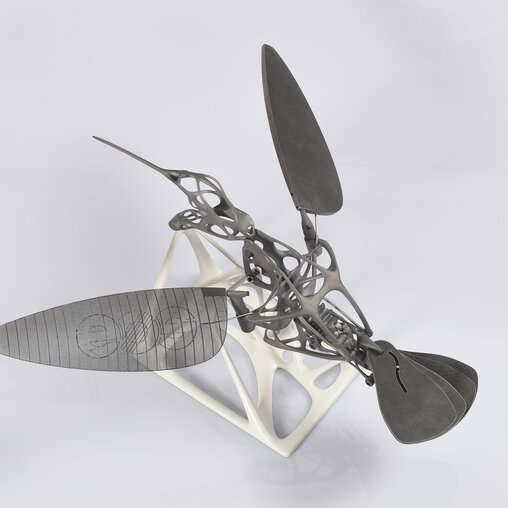

Let's fly together: The EOS Hummingbird Project

This project shows all the 3D printing advantages: complex geometries, lightweight construction and functional integration, with virtually no limits to design. Discover how EOS industrial 3D printing is changing the world of manufacturing.

3D Printing Advantages in Various Application Areas

The benefits of 3D printing are reflected in a variety of different industries. Be it aerospace, where every gram of weight saved is of economic importance and lightweight components represent a significant competitive advantage. Be it the field of medical, lifestyle and sports, where the focus is on customization and functional integration for implants, prostheses, visual aids and sports accessories. Be it the mobility and automotive sector, where massive savings in warehousing costs can be achieved through the on-demand printing of spare parts. Or be it the field of robotics and production, where complex geometries and functional integration are the buzzwords of the day.

Read application reports from our customers from a wide range of industries here and get an idea of how 3D printing could also change your production processes.