Build rate of up to 6.6 l/h with a packing density of 5%

Lowest price per part on the market

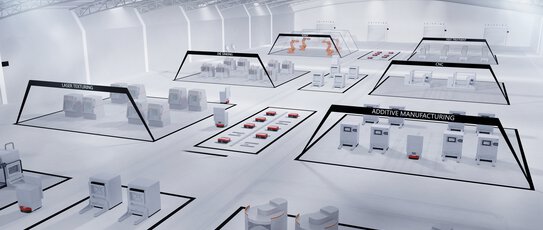

Automation-friendly platform with standardized software interfaces

Reduced Costs

The innovative layering system, which applies and compacts the material at up to 0.6 m/s, and the two powerful 70-watt lasers reduce the costs per part by more than 30%.

Diversity of Materials

The system processes high-performance plastics, enabling maximum diversity of materials. Application and material development are supported by open software interfaces and user-friendly tools.

Automation

The system is intuitively controlled by EOSYSTEM. Software integration in CAD systems, e.g. NX™ by Siemens, is provided by EOSPRINT 2, and a connection to ERP systems is provided by EOSCONNECT. Automated interfaces and optimized accessories reduce the cycle time and guarantee operational build times lasting several days.

Technical DataEOS P 500 |

Download Factsheet | pdf | 202,7 KB | |

| Construction Volume | 500 x 330 x 400 mm (19.7 x 13 x 15.7 in) | |

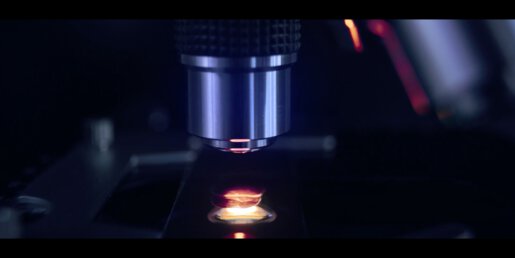

| Laser Type | CO₂, 2 x 70 W | |

| Precision Optics | F-theta lens, surface module, high-speed scanner | |

| Scan Speed | up to 2 x 10 m/sec (32.8 ft/s) | |

| Power Supply | 400 V / 100 A; max. power consumption 80 A | |

| Machine Dimensions (W x D x H) | 3,400 x 2,100 x 2,100 mm (133.9 x 82.7 x 82.7 in) | |

| Recommended Installation Space | min. 7.2 x 5.2 x 4.2 m (284 x 205 x 165 in) | |

| Weight | approx. 7,000 kg (15,432 lb) | |

| Software | EOSYSTEM with EOSAME feature, EOSPRINT 2 with SmartScaling feature and EOS ParameterEditor, EOSCONNECT Core, EOSCONNECT MachinePark, EOSTATE Powderbed |

Need information or want an offer? Get in touch!

Polymer Materials for the EOS P 500

EOS has exceptional materials expertise and a comprehensive portfolio of highly developed plastic and polymer materials for additive manufacturing. Our materials, systems and process parameters fit together optimally. With the right materials, you can realize the desired property profiles in the best possible way for your products.

more about polymer materials