Downloads

Get detail information with our whitepapers, which investigate the performance of a standardized test job layout built on three different EOS M 290 systems using EOS Titanium Ti64ELI or a study into the influence of oxygen in the print process chamber and its effect on the critical properties of aluminium alloy AlSi10Mg.

In a nutshell

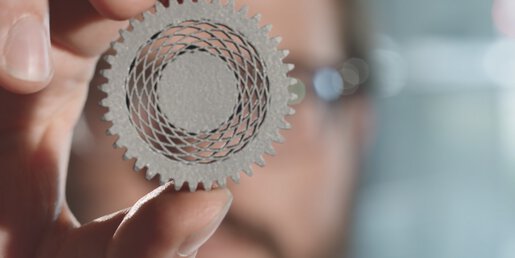

The most extensive materials portfolio on the market

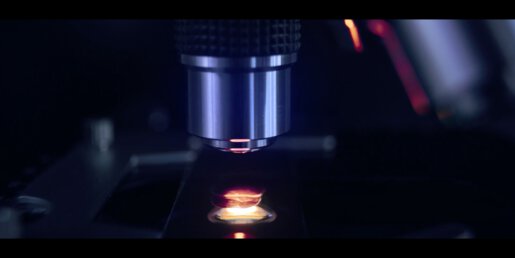

Powerful 400-watt fiber laser for excellent detail resolution

A robust and well-established system with a vast range of applications

Reproducible Part Quality

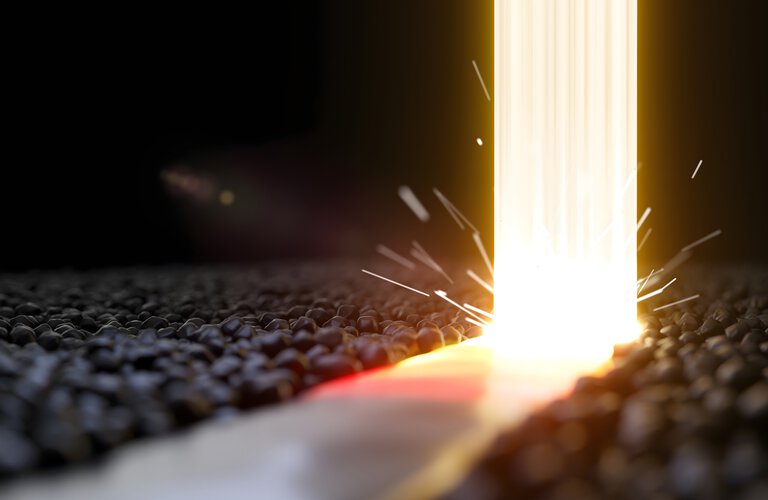

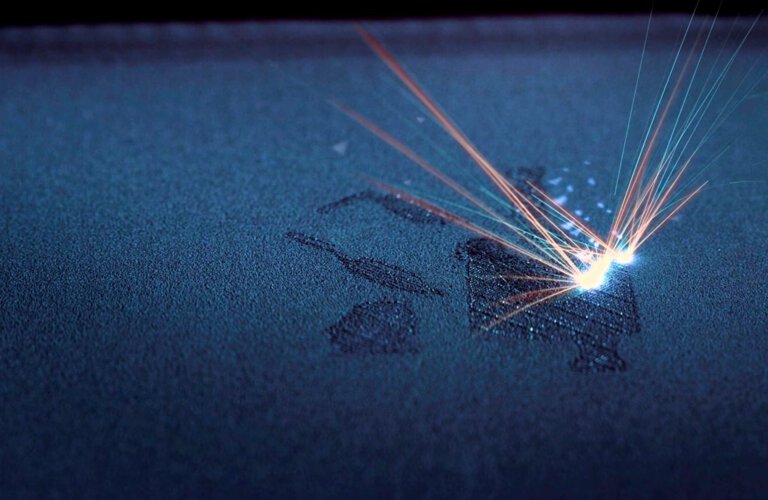

The exceptionally high beam quality of the laser spot and the excellent detail resolution are ideal for producing highly complex components with homogeneous properties.

Broad Portfolio of Materials

With the most extensive range of validated materials and processes available on the market, all customer needs are covered.

Comprehensive Quality Management

The comprehensive monitoring suite enables quality assurance of all production- and quality-relevant data in real time.

Technical DataEOS M 290 |

Download Factsheet | pdf | 440,4 KB | |

| Construction Volume | 250 x 250 x 325 mm (9.85 x 9.85 x 12.8 in) (height incl. build plate) | |

| Laser Type | Yb-fiber laser; 400 W | |

| Precision Optics | F-theta lens; high-speed scanner | |

| Scan Speed | up to 7.0 m/s (23 ft./sec) | |

| Focus Diameter | 100 μm (0.004 in) | |

| Power Supply | 32 A / 400 V | |

| Power Consumption | max. 8,5 kW/ average 2,4 kW/with platform heating up to 3,2 kW | |

| compressed air supply | 7,000 hPa; 20 m³/h (102 psi; 706 ft³/h) | |

| Machine Dimensions (W x D x H) | 2,500 x 1,300 x 2,190 mm (98.4 x 51.2 x 86.2 in) | |

| Recommended Installation Space | min. 4,800 x 3,600 x 2,900 mm (189 x 142 x 114 in) | |

| Weight | approx. 1,250 kg (2,756 lb) | |

| Software | EOSPRINT incl. EOS ParameterEditor, EOSTATE Everywhere, EOSCONNECT Core, EOSCONNECT MachinePark, Materialise Magics Metal Package and modules |

Whitepaper: Multi-Machine Capability Study Repeatability is Key for Distributed Serial Production

This whitepaper investigates the performance of a standardized test job layout built on three different EOS M 290 systems using EOS Titanium Ti64ELI. In a nutshell, the results verify that the EOS M 290

- Shows a high capability of more than 4 Sigma for the tensile properties across the three machines located in different facilities

- Proves that the DMLS process remains repeatedly capable and above the ASTM requirements for Ti64 ELI

- Verifies that EOS systems are ready for decentralized serial additive manufacturing

Want to learn more? Get the free Whitepaper and more here.

Whitepaper: EOS/Linde influence of oxygen in the print process chamber Effect on the critical properties of aluminium alloy AlSi10Mg

EOS and Linde combined forces to conduct an important study into the influence of oxygen in the print process chamber and its effect on the critical properties of aluminium alloy AlSi10Mg. This whitepaper describes the study and its findings:

- The EOS M 290 with the EOS Aluminium AlSi10Mg powder and process parameters enable a high-quality, reproducible final part

- An oxygen content below 1000 ppm needs to be maintained during processing to prevent increasing the number and size of pores and ensure high part density and required mechanical properties

- Powder aging is reduced by keeping the O2 level below 1000 ppm which enables more frequent reuse of the powder

- The position of the oxygen sensor influences the measurement, with a sensor placed near to the powder bed giving optimal measurement

Want to learn more? Get the free Whitepaper and more here.

Innovation Stories Customer References EOS M 290

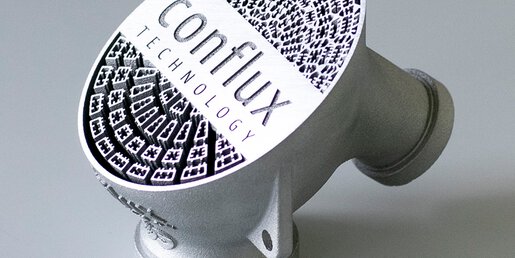

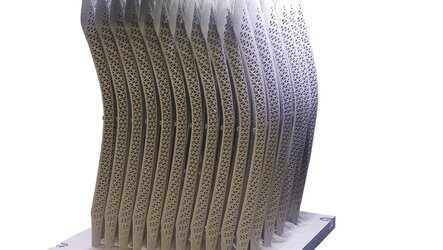

Example Applications 3D-Printed Parts From the EOS M 290

Metal Materials for the EOS M 290

The EOS M 290 has the most extensive range of validated materials and processes on the market.

more about metal materials