From innovative polymer blends to strong and versatile alloys, EOS additive manufacturing materials provide a firm foundation for efficient part production across multiple industries.

Raw materials are just as important to additive manufacturing (AM) as to traditional manufacturing processes. Computer-aided design (CAD systems), intricate layer-by-layer assembly methods and precise laser 3D printing won't produce sturdy, high-quality parts without leading-edge additive manufacturing materials.

We at EOS know how critical it is to choose materials that stand up to the demands of their use cases and working environment. The additive manufacturing materials we offer are developed with this philosophy in mind: The just-right material is essential — the almost-right option simply won't do.

Review the polymer, metal and alloy material options available from EOS for 3D printing and study their technical properties, strengths and key applications. The powders you'll find have undergone meticulous quality control measures throughout every phase of the supply chain, and are formulated to efficiently and effectively produce your parts in conjunction with EOS 3D printing systems and software.

Metal Additive Manufacturing Materials

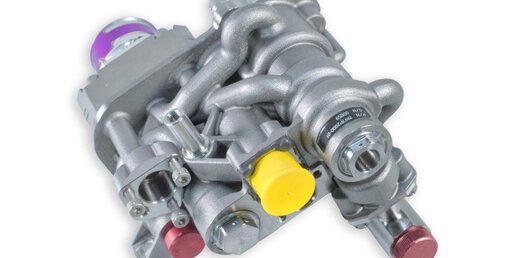

The parts being produced with metal in additive manufacturing represent some of the most exciting projects in the field. Metal powders have become a part of numerous exciting developments in various sectors, ranging from aerospace and health care to energy and automotive.

EOS is a globally recognized leader in Metal 3D printing DMLS technology. The metal powder options we offer were developed with this revolutionary additive manufacturing technique in mind. Our material portfolio includes more than 20 metals: Many are alloys, as the demands of the DMLS process and finished parts' environments often require physical and chemical properties that are reached by blending multiple metals. However, certain pure metals are available for specialized applications. Additionally, EOS experts are always striving to expand the metal powder portfolio to make the DMLS technology compatible with even more metals and alloys.

Additive alloys

It is no overstatement to say ingenuity in alloying changed the world forever. Following that same innovative spirit, EOS materials and metallurgy experts are always keen to develop and refine alloys that will shape the world to come.

Steel alloy powders — which boast high corrosion resistance, tensile strength and durability when shaped into finished parts— compose a significant share of the EOS additive manufacturing materials portfolio. Our offerings include stainless steel formulations ideal for a wide variety of applications ranging from shipbuilding to jewelry production. For more specific use cases, we offer case-hardening and tool steel.

Other EOS alloys range from highly versatile nickel and aluminum powders to titanium and cobalt chrome with remarkable hardness and tensile strength.

Pure metal powders

EOS metal 3D printers are compatible with several powdered pure metals:

Tungsten: This heavy, extremely heat-resistant refractory metal is vital for high-tech imaging devices, including X-ray guidance.

Copper: EOS engineers and metallurgists have begun working with powdered pure copper in recent years. Additively manufactured copper and copper-alloy parts are tremendously valuable in aerospace — or any other application requiring high electrical and thermal conductivity.

Plastics have been important to additive manufacturing since the technology's earliest days. The impressive mechanical and chemical properties of these powders make it ideal for Additive Manufacturing (AM). These characteristics similarly give 3D-printed plastics and polymers an edge in their main areas of application, such as aerospace, health care, rapid prototyping, the creation of key industrial components and more.

EOS uses the selective laser sintering (SLS) 3D printing process in our leading-edge plastics printers. As with our metal powders, the plastics and polymers and our portfolio all go through comprehensive quality assurance: Not only do our experts assess the materials themselves, but they also fabricate test parts to get a more accurate idea of their sturdiness in actual use environments.

Polyamide

EOS offers two nylon powders for additive manufacturing technology: white polyamide 12 (the most tested additive manufacturing material available on the market) and polyamide 11. Polyamides in both categories are used for rapid prototyping, automotive and aerospace. EOS offers flame-retardant variants of polyamide 12, and provides a climate-neutral polyamide 11 powder for customers looking to maximize sustainability.

PAEK

For applications requiring polymers that are not merely flame-retardant but fireproof, polyaryletherketones (PAEKs) are an ideal choice. As such, they are becoming increasingly prevalent in automotive, aerospace, rail and industrial applications. Additionally, because PAEK polymers are biocompatible and sterilizable, the medical device industry has embraced them for implant creation.

Thermoplastic elastomers

Because of their malleability, thermoplastic elastomers (TPEs) are useful for many contexts in which it's critical to bend without breaking. Examples include footwear and athletic gear, automotive tubes and gaskets, and parts traditionally made using foam or polyvinyl chloride (PVC).

Find the right additive manufacturing material for your application

If you're intrigued by what you've learned about the versatility and efficiency of additive manufacturing materials, we've only scratched the surface.

Find the right material for your production. We're happy to assist you.