TPE Materials - 3D Printing Elastomers TPU for SLS 3D Printer

Materials of the TPE polymer class have similar properties to elastomers – this means that they are flexible at room temperature but still remain dimensionally stable. When heated, they can be plastically deformed and processed like thermoplastics. Since they are easy to process, they can be used to replace cross-linked elastomers and soft PVC.

Fields of application: TPEs can for example be used to make damping elements, bumpers, bellows, soles, handles and hoses.

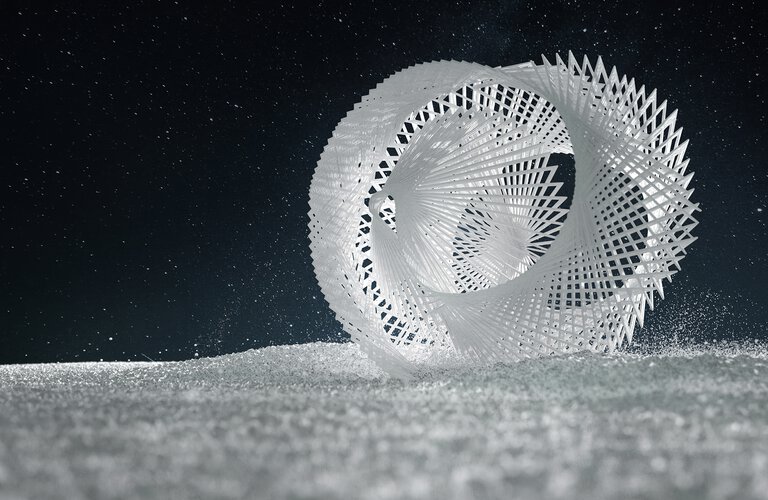

EOS TPU 1301 - Thermoplastic Elastomer White

The parts made from this white material are extremely hydrolysis-resistant, with high resilience and good tribological properties. The degree of flexibility can be influenced by the part design and the choice of process parameters and can even be varied within the same part.

Typical mechanical properties

| Tensile modulus | 60 MPa |

| Tensile strength | 7 MPa |

| Elongation at break | 250% |

Thermal properties

| Melting temperature (20°C/min) | 138°C |

Physical properties

| Density | 1080 kg/m³ |

Material processed by