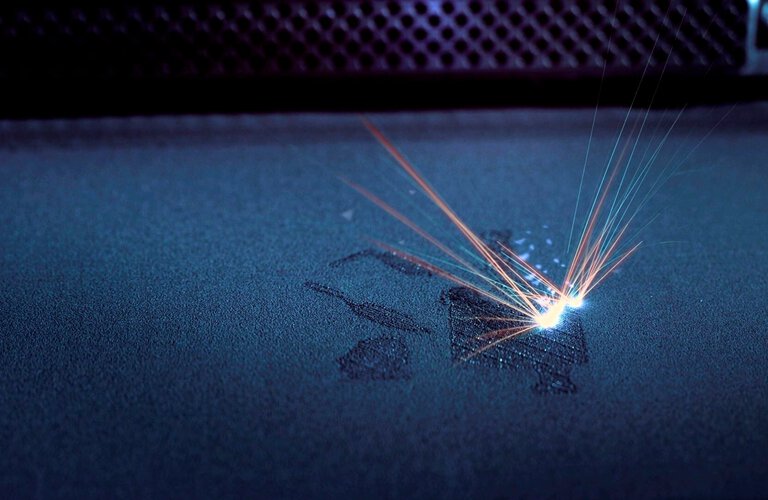

Tool Steel Alloys for Industrial 3D Printing

Tool steel’s material characteristics make it ideal for a wide range of tooling applications across all industries.

The tool steel family of powders encompasses the MS1, 1.2709, CX and CM55 alloys. All these powders are designed and tested for use on EOS’ metal systems.

All EOS 3D printing tool steel powders are shipped with an inspection certificate (according to EN 10204, Type 3.1) showing the results of the extensive QA testing not only of the powder itself but also of test parts built on a dedicated 3D printer with a dedicated process.

EOS also offers a wide range of validated processes for each of the above materials. These offer the optimal combination of parameters (e.g. laser power, layer thickness, etc.) in order to ensure that the properties of the 3D printed part are consistently achieved.

EOS MaragingSteel MS1

Parts show very good mechanical properties being easily heat treatable using a simple thermal age-hardening process to obtain excellent hardness and strength.

Typical Part Properties

| Chemical composition in compliance with | 18Ni300, M300 |

| Ultimate Tensile Strength | 2080 MPa |

| Yield Strength | 2000 MPa |

| Elongation @ Break | 4 % |

EOS StainlessSteel CX

Parts show good corrosion resistance combined with high strength and hardness plus excellent wear and fatigue resistance. This combination is ideal for tooling applications in medical, food and other industries.

Typical Part Properties

| Chemical composition in compliance with | Precipitation hardening tool steel |

| Ultimate Tensile Strength | 1720 MPa |

| Yield Strength | 1650 MPa |

| Elongation @ Break | 6 % |

EOS ToolSteel 1.2709

Parts show excellent mechanical properties and fatigue strength being heat treatable to various needs to obtain application appropriate hardness and strength.

Typical Part Properties

| Chemical composition in compliance with | 1.2709 |

| Ultimate Tensile Strength | 2250 MPa |

| Yield Strength | 2160 MPa |

| Elongation @ Break | 3.5 % |

EOS ToolSteel CM55

This material is a cobalt free ultra-high strength steel for cold and hot-working tools as well as engineering solutions. It’s alloying elements and moderate carbon content form a strong and stable structure for demanding applications.

Typical Part Properties

| Ultimate Tensile Strength | 1730 MPa |

| Yield Strength | 2030 MPa |

| Elongation @ Break | 4 % |