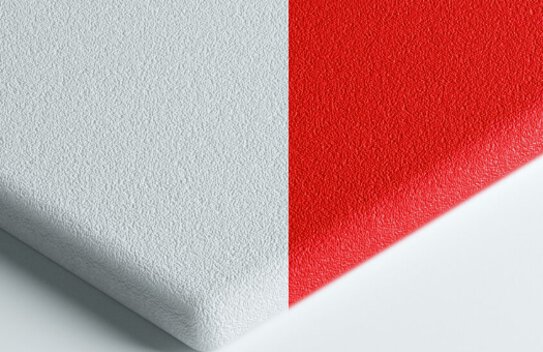

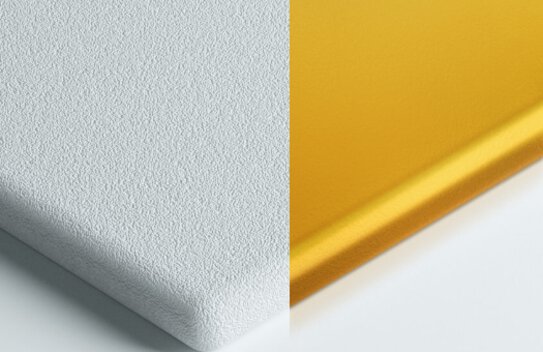

Parts from the 3D printer are fully functional straight away. Their natural surface has a sand-like, grainy appearance and feels slightly rough to the touch. This surface finish is not ideal for some applications. The surface can be refined with various post-processing methods.

Post-Processing Methods

Dyeing

Process description

The surface of the part is colored homogeneously in a water bath. Using pressure and heat, the colors penetrate into the plastic by means of a chemical reaction.

Properties

- Unlimited selection of colors for white parts

- No material deposit, part geometry is unchanged

- ISO certified colors