The quality assurance and process monitoring features of EOSTATE Exposure OT — now in a comprehensive package together with training, consulting and game-changing features like

Smart Fusion.

Ensuring reliable production quality is important to all additive manufacturing (AM) projects and especially so to industrial metal 3D printing. The EOS Smart Monitoring* Plan is the ideal solution.

EOS Smart Monitoring includes all of the end-to-end monitoring capabilities critical for series production, and the cutting-edge automation of Smart Fusion makes a viable business case for more applications.

*requires an active EOS Build/Build+ Plan

Exposure OT: 100% Insight

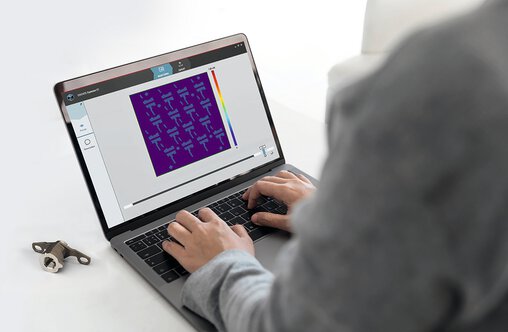

Smart Monitoring includes EOSTATE Exposure OT, an ingenious pairing of hardware and software by utilizing optical tomography for process insights.

- A high-resolution near-infrared camera records and measures the energy input in real time — regardless of part size. The long exposure time of the camera facilitates better analysis of the build's individual layers

- Based on analysis algorithms (uniquely adjustable to meet individual project requirements), EOSTATE Exposure OT provides a toolbox to determine process flaws

- This allows you to forgo destructive testing and is less expensive than other non-destructive testing methods, such as X-ray and CT scanning. Thus, you can eliminate the need for costly downstream quality assurance and can ultimately reduce your scrap rate and percentage of build failures

- Insights derived from EOSTATE Exposure OT are important for future production cycles and to speed up product development

- There may also be necessary inclusions in documentation required by regulatory bodies in highly regulated industries (e.g., aerospace, medical and automotive)

- Ultimately, EOSTATE Exposure OT's insights help build trust in additive manufacturing technologies and processes, as the data allows you to prove the feasibility and repeatability of your application

Smart Fusion: A Game-Changer in Additive Manufacturing

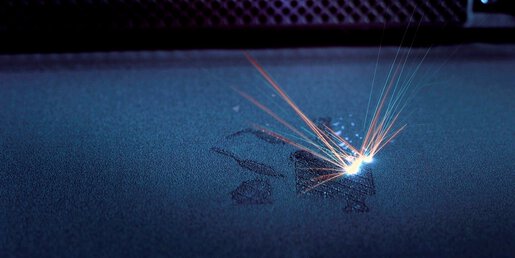

Smart Fusion brings a degree of control to metal 3D printing that even those in the AM industry might not have thought possible just a few years ago.

The automated feature adjusts laser power levels to match the standards established in pre-processing, making corrections during the build as needed. Exposure OT's heat distribution monitoring is critical to the process, as its data informs Smart Fusion's power corrections during the build. Smart Fusion reduces the likelihood of overheating and helps ensure fewer part iterations.Smart Fusion’s benefits improve the entire EOS software landscape. AM designers who know Smart Fusion, can craft part designs optimized for supportless building.

Critical OT Training

Those unfamiliar with utilizing OT for AM monitoring and QA — or who want to strengthen their knowledge of the technology — can learn everything they need via Smart Monitoring's training features. Each Smart Monitoring per-system subscription includes:

- Up to two e-learning seats for basic and advanced OT training, as well as advanced e-learning for Smart Fusion

- Entry to one four-hour expert session for OT technology and one Smart Fusion expert session

Subscription-Based Flexibility

Instead of a prepaid upfront investment in the hardware and software required for EOSTATE, EOS Smart Monitoring users only need to subscribe to a yearly subscription per 3D printing system. (min 2 years at the beginning) If you've purchased a new EOS metal AM system that features preinstalled OT, you can try EOS Smart Monitoring before subscribing. Either way, each EOS Smart Monitoring subscription includes the required hardware.

The subscription model gives EOS Smart Monitoring customers the freedom to scale their usage as needed. If Smart Fusion isn't required for your business after your initial commitment, you can deactivate it, and potentially opt back in at a later date if operational demands change.

Inactive EOS Smart Monitoring users retain the OT hardware and some Exposure OT functionality (e.g., access to historical OT data). However, they lose access to certain critical features — notably, the ability to record real-time OT data and analyze it on the fly. Also, inactive subscribers will no longer have access to training resources and Smart Fusion (which relies upon live data from Exposure OT to serve its key purpose).

Downloads

Success Story voestalpine Shorter Time to Market for AM Tooling Inserts

Thanks to their high level of customer intimacy and technological familiarity, voestalpine develops tailor-made solutions for their plastic injection molding (PIM) customers. These are manufactured with the EOS M 290 system and optimized with EOS Monitoring solutions enabling a faster development of the process parameters, reduction of printing costs due to fewer job iterations and a reduction of the quality assurance costs. Learn more about voestalpine’s approach and results in the success story.

EOSTATE Exposure OT and MeltPool Monitoring gave us a deeper understanding of the interactions taking place between the various factors that influence the LPBF process. Not only were we able to minimize the development cycles of novel materials during the qualification phase but we were also able to benefit from faster build rates and lower lead times for production.

Success Story MTU Significant Savings in Quality Assurance

With the goal of finding a specific testing procedure for 100 % monitoring and documentation of the AM process, the engine manufacturer MTU Aero Engines began developing optical tomography (OT) in 2013. Based on their work, EOSTATE Exposure OT was developed in collaboration with EOS.

MTU Aero Engines has now been using EOSTATE Exposure OT for years for process development and quality assurance in the additive series production of borescope bosses for Airbus A320neo engines. This has allowed them to completely eliminate any downstream quality assurance procedures.

EOSTATE Exposure OT is able to determine when a part is not flawless. Because of this, we were able to completely dispense with subsequent X-ray and CT inspections in the series production of borescope bosses. Economically, this is a huge advantage.

Whitepaper: Correlation of In-Process

Monitoring Data and Mechanical

Properties of Lattice Structures

The monitoring system EOSTATE ExposureOT can be used to assess the relative density and compression strength of lattice structures. Any decrease in energy density that results in a lower EOSTATE ExposureOT value leads to a decrease in strut thickness and therefore a lower relative density.

This whitepaper gives information about:

- Producing or planning on producing porous structures by means of additive manufacturing

- Assessing mechanical properties of lattice structures during the build

- State-of-the-art alternatives to cost-intensive quality assurance methods

Whitepaper: Correlation of In-Process

Monitoring Data and Defects

in X-Ray CT for AM Swirler

The EOSTATE Exposure OT monitoring system can be used to identify defects. This study shows that process instability can be reflected as extreme hot spots, which can be detected by the monitoring system.

This whitepaper gives information about:

- The assessment of the sensitivity of EOSTATE Exposure OT and EOSTATE MeltPool monitoring system in registering variations in melt pool energy density when processing EOS NickelAlloy IN625 on EOS M 290

- The correlation of defects based on in-process monitoring data and CT scanning

- The application of in-process monitoring for quality assurance in a serial production scenario