Reliable Part Properties as a Basis for Additive Series Production

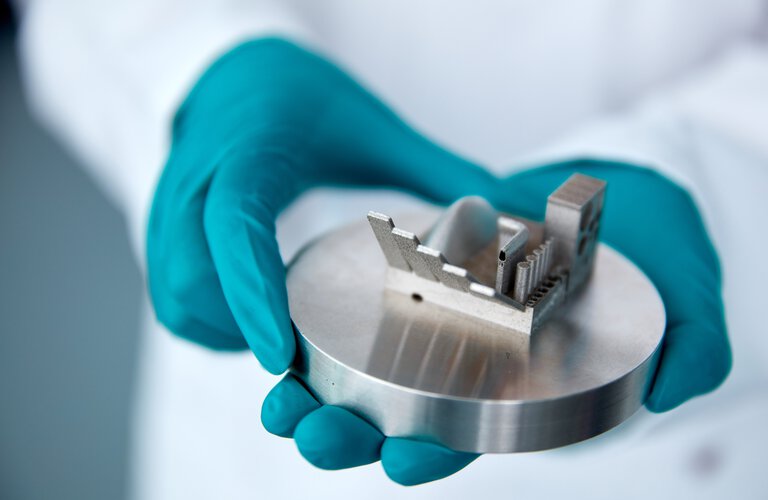

EOS classifies the technological maturity of all self-developed 3D printing SLS polymer materials and 3D printing metal materials and processes using Technology Readiness Levels (TRLs). The TRL concept was developed by NASA and has since established itself in various industries. For example, Level 5 corresponds to verification of the technical solution, whereas Level 9 corresponds to full production capability with extensive statistical data. By providing valid parameters for part properties, EOS makes your transition to additive series production faster and easier.

EOS also divides its materials and processes into two categories, CORE products span TRLs 3 to 6, and PREMIUM products span TRLs 7 to 9, which are ready for use in series production. One of the goals of this system is to offer new materials on the market with a clear value proposition.

Quality in Industrial 3D Printing: An Integrated Method

EOS has more than 30 years of expertise in materials in the metal and polymer sectors and offers a broad portfolio of materials for additive manufacturing.

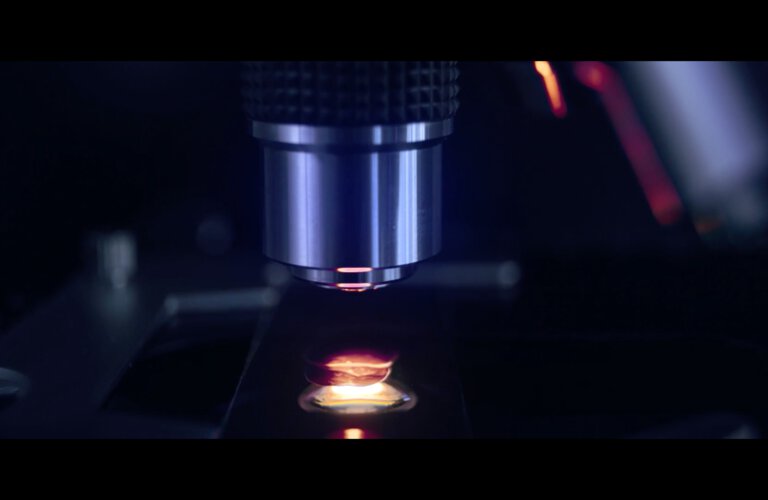

3D printing is about quality. Consistent and reproducible part quality is essential for series production applications. Especially industries such as the aerospace, automotive, and medical sectors require tested and consistent part quality. But how does this work for 3D printing, or additive manufacturing? Discover how EOS has established a quality management system that is unrivaled in the industry.

At EOS, the development of systems, materials, process parameters, software and services has always gone hand in hand. All elements fit together perfectly. The result is a uniform and repeatable high part quality at competitive unit costs. Especially in series production environments, this combination is of crucial importance.