A Complete Process Chain From a Single Source for Additive Manufacturing With Foams

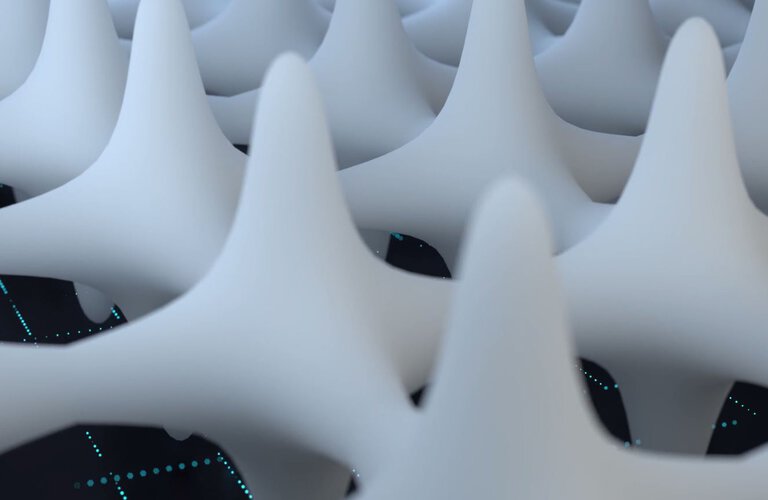

Foam has found its way into 3D printing: this flexible material can be used to manufacture more comfortable, safer and lighter products that can be individually customized.

* Digtial Foam™ is a registered trademark of EOS GmbH.

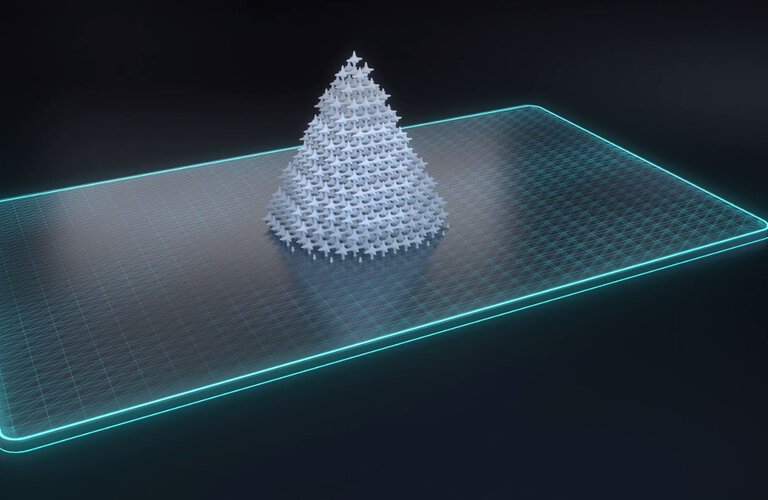

The EOS Digital Foam Program

The Digital Foam program by EOS accelerates the development and production of 3D-printed foams for applications like helmets and soles. This solution, designed by EOS, combines product design (CAD), materials, part qualification, and 3D printing (additive manufacturing). The program brings these variables together harmoniously to allow new ideas to be implemented more quickly. Instead of having to find solutions for individual elements of the process chain, Digital Foam enables companies to produce additively manufactured helmets, customized orthopedic aids and high-performance shoes, as well as many other products, more quickly.

Applications of Additive Foams Helmet Inserts From Polymer 3D Printer

The Digital Foam process chain begins with engineering software, which helps you to simplify the design, analysis, and the preparation process. Digital Foam is already being used by Bauer Hockey, the global leader in hockey equipment innovation, in the MyBauer custom equipment program. In collaboration with EOS, Bauer uses the Digital Foam approach to scan a player’s head, create a digital file, and leverage Selective Laser Sintering (SLS) to print a helmet insert that fits perfectly to the wearer. The result is a lightweight and completely customized protective helmet product, manufactured in a flexible mass production environment, and perfectly tailored to the customer’s digital scan.