Over the next 10 to 20 years, we expect manufacturing to undergo significant changes. Away from part production using company-owned and cost-intensive facilities, toward more cost-efficient, outsourced production in digital factories. These factories will be able to manufacture products that currently require separate production lines in parallel and in series.

The path to the future

Order processing will be automatically controlled within a global network of connected 3D printing cells or digital manufacturing cells. Production volumes and capacities will be verified and scheduled accordingly. Besides significantly higher flexibility, logistics will also become more sustainable, since production unfolds on site. This is relevant in every industry, from demanding industries such as the automotive, aerospace & defense and medical sectors to the spare parts sector.

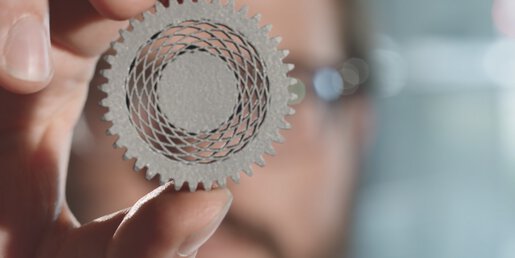

To fully exploit the innovation potential of additive manufacturing (AM), an integrated digital transformation is required. Production facilities and systems, the production layout and all of the factory’s work processes need to be digitalized.

to set up exactly the digital manufacturing facility

that meets your needs best.

Set Up Your Digital Manufacturing Facility We Can Support You With the Digital Transformation of Your Entire Supply Chain

Our technical consulting combines 3D printing know-how from a variety of industries. We plan, implement and optimize digital factories with additive manufacturing and determine the ideal way to integrate industrial 3D printing into your production environment. We help you develop solid foundations for your Industry 4.0 to support digital twins, digital threads, digital marketplaces, and other future-oriented digital concepts.

We determine which steps are necessary to set up and commission your digital production facilities, analyze the production requirements together with you, define the necessary KPIs and discuss every key aspect of successful implementation. With our pilot production lines we verify production throughput, part quality, and business cases for critical parts.

Are you looking for the right solution for your digital production? Get in touch!

To meet their production requirements, Premium AEROTEC opted for 21 EOS M 400-4 machines with the EOS Shared Modules concept to achieve higher utilization rates. This concept helps to automate the full process chain by allowing work steps to unfold in parallel and guaranteeing high machine availability.