Additive Manufacturing for Motor Sports Realize Potential With EOS 3D Printing Systems

Simplified implementation of lightweight structures

Simplified implementation of integrated functionality

Drastically reduced lead time, faster iterations

Faster, lighter – and always safe: these are the requirements of motor sports development. For decades, EOS has been working with customers to exploit new potential using industrial 3D printing.

Besides precisely defined functional properties, low weight and high strength count the most. There are similar requirements on the choice of manufacturing technology: it needs to allow innovative and often unusual designs. It must allow parts and their variants to be manufactured quickly, with minimal effort and cost.

3D Printing Application Examples From Motor Sports

EOS Solutions for the Formula 1 Team Front Wing Design at Williams Martini Racing

Williams Martini Racing was looking for a simple, fast and cost-efficient solution to build design prototypes for the front wing of their Formula 1 race car. Additive manufacturing by EOS offered the perfect complement to their development and manufacturing processes. With the EOSINT P 760, the team succeeded in building various iterations, as well as lower costs thanks to reduced production times.

EOS has the experience and professionalism that our employees display everyday at work. We’re not just a racing team, we’re also an engineering company. All of our products and race cars are based on technically advanced decisions. The same is true at EOS.

Want to find out more? We’d be happy to advise you about custom production solutions.

EOS Customer Reference Racing Supplier Pankl Racing System

EOS Solution for Motorcycle Racing Additive Manufacturing of a Footrest

Pankl Racing Systems is a systems supplier for motor sports, high-performance vehicles, and the aviation industry.

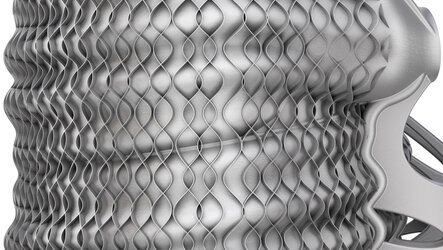

Making complex lightweight components quickly without compromising on safety is one of the challenges faced by the company. With additive manufacturing solutions by EOS, the Austrian company has successfully realized various iterations of topology-optimized motor sports parts.

Case Study Formula Student Industrial 3D Printing for Electric Vehicles

Whether you need to build a lightweight, compact battery container with integrated cable and cooling channels for an electric race car or develop a lightweight but highly rigid wheel carrier: Formula Student takes advantage of additive manufacturing to accomplish leading innovations.