Additive Manufacturing of Glasses Made to Measure or Customized Serial Products

Every person’s face is as unique as their personality. To meet the highest fitting standards, glasses frames need to be made to measure. However, they are comparatively expensive to manufacture by hand.

Industrial 3D printing can change this. As an alternative to traditional manufacturing processes, it offers a range of advantages.

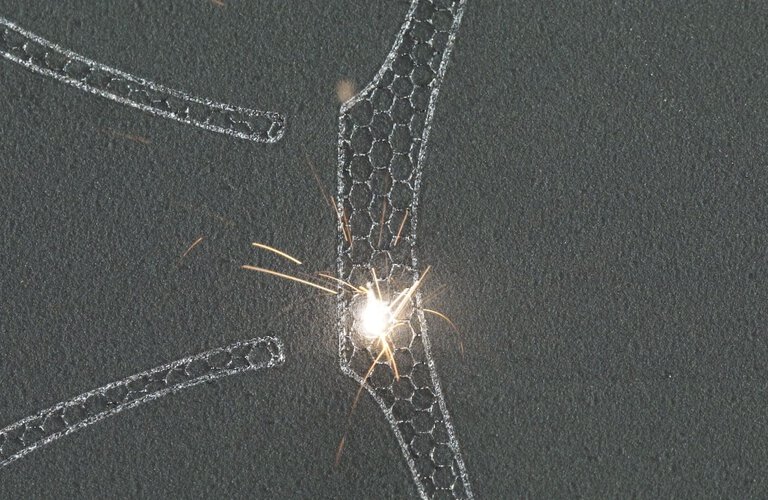

3D manufacturing systems enable you to make metal and plastic glasses frames that meet the highest demands with their lattice structure, design and aesthetics. After recording the shape of the customer’s face with a scanner and processing the data, the 3D printing system can quickly build a glasses frame that is tailored to the wearer. This makes it possible to quickly implement custom design requests and even manufacture small series products in a cost-efficient setting.

Stylish and exclusive, but also cost-efficient: additive manufacturing unlocks deep-reaching potential when manufacturing glasses frames.

The results of the three-way collaboration between Hoet, Raytech and EOS not only help customers to see, they are clearly visible themselves: the diverse delicate and complex lattice structures of the frames would not have been possible with conventional methods.

Additive manufacturing with the EOS M 290 3D printing system allowed the classical design to be made with a certain extra something for the first time ever. The innovative technology also achieves optimizations in terms of sustainability, cost reduction and comfort.

Fitz Frames USA Additive Manufacturing of Customized Glasses Frames by EOS

Discover how Fitz Frames collaborated with EOS and Additive Minds to develop a comprehensive 3D printing process and deliver industry-leading custom glasses.

Fitz Frames also uses the innovative technology for a collaboration with “Vision to Learn” to offer free eye exams and custom glasses for children in need.

Success Story You Mawo Series Production of Custom Eyewear

The innovative start-up You Mawo develops and designs glasses that are individually tailored to the customer. The glasses frames are made with EOS 3D printing technology. Since they are based on a scan of the customer’s unique face shape, they are completely tailored to the specific needs of the wearer. The glasses are made from the material PA 2200 on the EOS P 396.

EOS systems allow a wide range of benefits to be achieved:

- 30 % lighter than acetate

- Improved durability

- Significantly reduced time-to-market

- Less overproduction and shorter delivery paths

- White raw material, ideal for dyeing

- Anti-allergenic