Additive Manufacturing Process for Dental End Products

Partial dentures need to fit the patient without any compromise, as well as looking natural and aesthetic. Ideally, they should also last forever. Bridges, crowns and model cast prostheses are usually manufactured by hand – a complex and cost-intensive process.

Industrial 3D printing is a more cost-efficient and precise alternative for dental laboratories and manufacturing service providers. It is characterized by consistent and repeatable part quality, as well as high reproducibility.

Advantages of Additive Manufacturing for Dental Products

CAD-CAM in the Additive Process Our 3D Printing Solutions for Crowns and Bridges

Additive manufacturing with EOS systems for dental prosthetics

Whether you’re getting started with the additive manufacturing of dentures for the first time or you want to expand your existing production capacity: we have complete solutions from a single source with systems, materials and training. In this way, we offer full control over all quality-relevant processes and a truly end-to-end solution that meets the highest possible standards.

How you can benefit from our 3D printing system for the cost-efficient manufacturing of dentures:

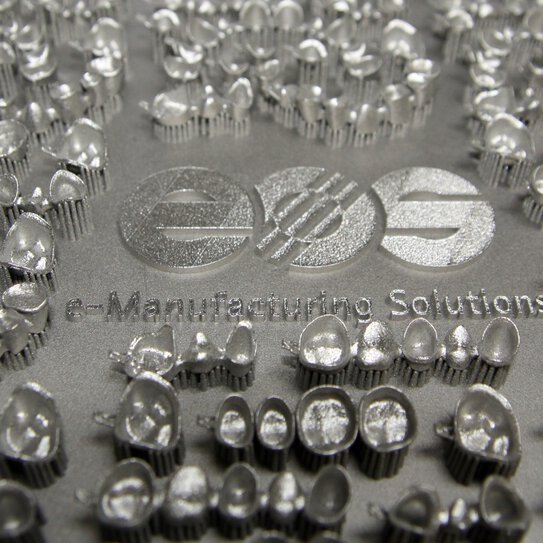

- Significantly higher output with less material usage: the manufacturing capacity of the EOS M 290 for crowns and bridges achieves 75 units per build job on average; the EOSINT M 270 achieves a capacity of up to 450 units

- Reproducible quality while also optimizing unit costs: costs are reduced thanks to the high productivity – while achieving consistently high quality for the end products

- There are no tool costs

- Additive manufacturing technology can be implemented quickly and very flexibly

Open process

Our process chain offers great flexibility thanks to its open system interfaces. The user can choose between modules as required and exchange data between them. EOS systems work with STL data (STL = Surface Tessellation Language, a standard format for 3D data), which allows dental technicians to take advantage of various computer-aided design software (3Shape, Dental Wings, Exocad, etc.). Thanks to the independent system structure, the digital CAD-CAM process can be adapted to suit the business, indication-specific and technical dentistry requirements of your medical practice or laboratory to achieve an optimal manufacturing process.

Still have questions? We’d be happy to advise you about custom production solutions.

Materials and Processes by EOS

Our metal powders meet the high requirements placed on medical products. All testing and processing is conducted in cleanrooms.

We offer support for all aspects of process introduction for dental laboratories and other manufacturing service providers.

EOS systems are capable of manufacturing medical products. However, EOS cannot guarantee that these products meet all requirements.

Our package for 3D-printed model cast prostheses

For model casting, EOS solutions achieve extensive time savings. Designing a model cast prosthesis takes just 15 minutes. The EOSINT M 270 system can be used to make model cast prostheses. It works very accurately, makes laboratory work easier and produces approx. 48 units per day with consistent quality. All material and application properties are compatible with one another. The technology can make structures that are more delicate than is possible with conventional casting techniques. High detail rendition supports the reproduction of grained structures.

EOS systems are capable of manufacturing medical products. However, EOS cannot guarantee that these products will meet all requirements.