Additive Manufacturing of Plastic Housings

Having a stable housing protects the interior. Robust cases are often essential, especially for sensitive electronics. They need to be strong and properly sealed, while also fitting as closely as possible, and they need to be manufactured quickly enough to achieve short production cycles. However, with the injection molding process, manufacturing housings with these properties is only viable in very large series productions.

Industrial 3D printing offers a cost-efficient alternative for the small and medium series production of plastic housings. Whether made from materials with insulating or especially favorable dissipation properties, the additive manufacturing of housings is characterized by cost efficiency, design freedom and functional integration potential.

What Our Customers Have to Say Statements About Our 3D Printing Technology

We optimized the dimensions of our parts, as well as their weight and stability, while also integrating functionality directly into them – all in the same part. Thanks to the reliability and precision that we achieved, special police and military units throughout Europe are now using our lamp.

When we were examining the costs of 3D printing, we realized that the machine would pay for itself within a year if we used it to manufacture both products. At that point, the right decision was clear.

Advantages of Industrial 3D Printing for Manufacturing Housings

Success Story Canto 3D-Printed Dive Lamp

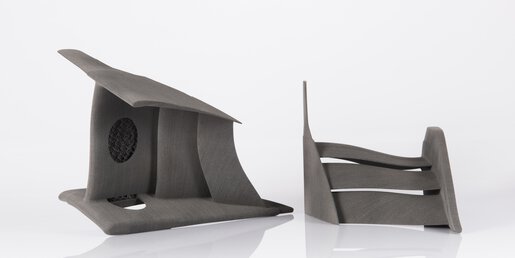

Canto Ing. GmbH wanted to develop an underwater dive lamp that would be smaller, lighter and more robust than anything else on the market. They succeeded in solving this challenge with an EOS system.

The lamp connection is additively manufactured to allow the internal system, which features a spring latching mechanism, to be produced in a single piece. This allowed the number of assembly parts to be reduced from 3 to 1. Weighing just 580 grams, the lamp is setting new standards. As an added benefit, Canto Ing. GmbH were spared the need to manufacture an expensive injection molding tool, which would have cost up to € 35,000.

The lamp was made manufactured on an FORMIGA P 110 with the material PA 2200.

Success Story 3D Printed Camera Housing for Outdoor Use

The challenge was to manufacture a low number of units of a robust camera holder with a complex design. The housing needed to be flexible enough to hold six cameras. At the same time, the production process needed to be open to support later design iterations without causing issues.

Thanks to EOS technology, a product design was successfully realized that would previously have been impossible.

The partnership with Freedom360 allowed design changes to be made rapidly. Midwest Prototyping were able to implement cost-effective production in small quantities.

Find out more about this success story in the video.