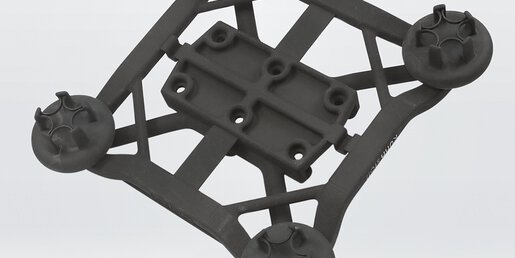

Integrated construction with reduced complexity and shorter assembly time

Less wastage in the working process

Low weight through utilization of polyamide and integration of functions

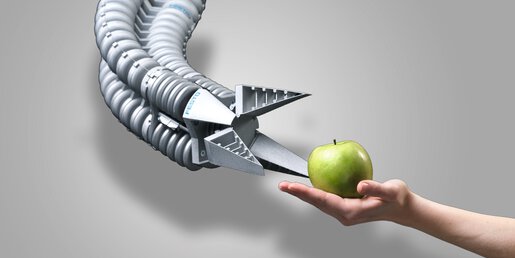

The successful use of the lightweight robotic hand shows that when it comes to special requirements, special solutions are necessary and that these can be realized. With EOS and its innovative systems, we certainly have the right partner.

Additively Manufactured Robotic Hand for Pharmaceutical Supplier Theo Hillers GmbH

Theo Hillers GmbH was searching for a solution for the handling of sieves and their sprues (the waste piece on a casting left by the hole through which the mould was filled). The solution was to be docked on a sprue removal device, often known as a sprue picker. For a number of reasons, standardized automation technology had reached its limits. The problems included the continued utilization of the existing sprue picker, the number of small cavities in the tightest of spaces, increased quality requirements, limited space and a maximum weight of the robotic hand of about 500 g.

Known at ASS as PA-Forming, Additive Manufacturing offered the best solution because it allowed for the continued use of the customer‘s existing system. The EOSINT P 390 system from manufacturer EOS was used.

For the first application, a lightweight robotic hand was produced from polyamide in the form of a star. With the innovatively produced, extremely light and compact robotic hands, the pharmaceutical supplier was able to increase its process reliability and thereby more than compensate for the slightly higher costs of production.

The Results at a Glance

This solution, other than the conventional systems from aluminium profiles, has fulfilled both our expectations in terms of handling and our fundamental aim, which was the reduction of wastage.