Efficient Spare Parts Logistics With Additive Manufacturing

Spare parts management comes with a long list of challenges: high storage and logistics costs, overproduction caused by minimum purchase volumes, and long waiting times are standard and prevalent. Sometimes, the supplier is no longer offering the part by the time it is needed. An example of this is, trains and buses are usually in service for 20+ years, so when there is the need for spare parts, most are usually discontinued.

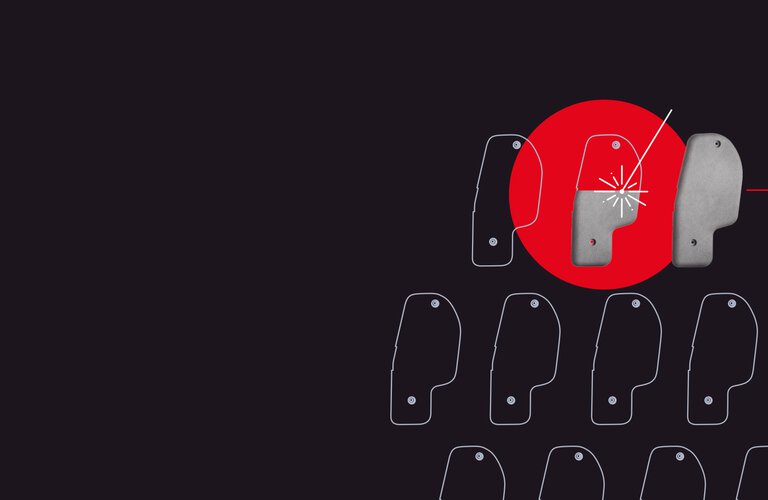

Additive manufacturing offers a solution: Spare parts made from metals or plastics can be produced on demand by the 3D printer without tools and in the exact quantity required, without a minimum purchase volume. This avoids unnecessary overproduction and guarantees maximum customer satisfaction. The underlying idea: instead of resource-intensive warehouse logistics, the CAD data of the spare parts are saved and only sent off when necessar, a decentralized and highly efficient process.

The Advantages of What 3D Printing Has to Offer for Spare Parts Management

Want to find out more? We’d be happy to advise you about custom production solutions.

In order to be more profitable, EvoBus GmbH, a subsidiary of Daimler AG, set themselves the objective of making their spare parts production system more efficient.

The goal was to reduce the production, storage and logistics costs of approximately 300,000 spare parts using additive manufacturing technology.

After identifying well over 2,500 parts suitable for production with 3D printing, 35 of these parts were manufactured as a trial and it was successful: EvoBus GmbH was even able to begin the production of spare parts earlier than expected.

EvoBus GmbH successfully achieved their goal of increasing profitability and efficiency.

Spare Parts When You Need Them, Not Determined by Contractual Obligations Deutsche Bahn Relies on 3D Printing

Additive manufacturing can help benefit your supply chain, especially when it comes to mobility. In this industry, having a steady and reliable source of spare parts is essential. At the same time, most of the spare part costs are due to storage and logistics. Additive manufacturing enables spare parts to be manufactured lightning-fast on demand, eliminating tool and storage costs. This also increases the efficiency, since production can occur with exactly the right number of parts.