Together We Will Enhance Your Success

Our e-manufacturing partners work closely with us to increase the acceptance of e-manufacturing as a manufacturing process for end products. They highlight the advantages of e-manufacturing, carrying

out projects as demonstrations, and continuously striving to improve the technology.

Expertise & Resources

With their EOS systems and capabilities, our

e-manufacturing partners can make your production projects a reality. They provide technical knowledge to support the common goal of developing your production process.

Services

Receive advice on how to derive the maximum benefit from e-manufacturing with a focus on consistently implementing e-manufacturing processes.

The lessons learned are systematically reincorporated to improve the e-manufacturing process.

Quality

All our e-manufacturing partners maintain a high level of quality standards (e.g. ISO 9000) to ensure your e-manufacturing projects turn into success stories.

We have been using EOS technology for more than eight years and have always had positive experiences. When used correctly, the design freedom provides significant benefits that give our customers market advantages that are nearly unrivaled.

How to Become an e-Manufacturing Partner

All e-manufacturing partners are exclusively appointed by invitation from EOS. One prerequisite is you must share our vision of additive manufacturing as a production method and profitably communicate this message on the market. Our partners have extensive process know-how, which helps them create value from 3D printing beyond rapid prototyping.

In addition, they provide insights and best practices back to us, making it possible to implement success stories effectively across a range of industries.

Our partners are fully committed to e-manufacturing solutions from EOS and integrate e-manufacturing into their marketing and sales activities. Conversely, EOS promotes the e-manufacturing partner network on the market.

3D RPD is a market leader in rapid prototyping and manufacturing. The company produces functional and display models using industrial 3D printing, as well as end products. 3T RPD is the largest 3D printing service company in the UK for both plastic and metal parts and operates three EOSINT M 270 systems. 3T RPD provides intensive consulting to its customers to ensure that they always receive the best quality, delivery and service to meet all of their requirements in the prototyping and end product businesses. In this way, the company contributes to the development of new products and assists with early and rapid market launches.

3T additive manufacturing

Fulton Court, Wofford Way

New Greenham Park / Newbury

Berkshire RG19 6HD

United Kingdom

Contact:

Ian Halliday

Tel. +44 1635 580 284

Fax +44 1635 569 857

enquiries@3t-am.com

www.3t-am.com

The vision of the Central University of Technology (CUT) is to be a globally integrated technical university in South Africa that focuses on national needs and supports graduates by providing them with skills and competencies in relevant technologies. CUT uses five EOS systems, including the titanium version of the EOSINT M 270 and two plastic laser sintering systems. The institute is currently working on academic research projects and remains in close contact with South African companies on topics such as application development and technology transfer, dissemination and demonstration.

Central University of Technology, Free State

Private Bag X20539

BHP Biliton Building

ZA-9300 Bloemfontein

South Africa

Contact:

Deon De Beer

Ludrick Barnard

Tel. +27 51 507 3253

Fax +27 51 507 3554

www.cut.ac.za

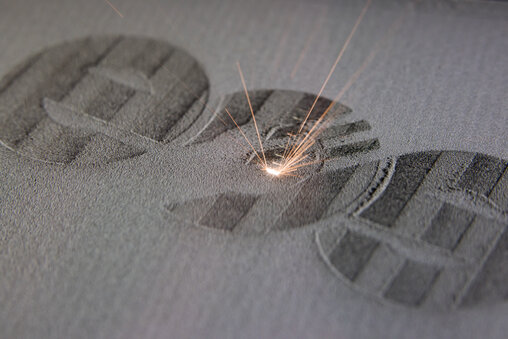

FKM Sintertechnik was founded in 1993. Today, it is the largest service company that uses EOS plastic laser sintering technology. FKM is currently operating 21 EOSINT systems for plastic laser sintering (including PEEK HP3) and direct metal laser solidification (DMLS). FKM is the ideal partner if you want to undertake large-scale production projects with laser sintering.

FKM GmbH

Zum Musbach 6

35216 Biedenkopf

Germany

Contact:

Mr. Dehnert

Tel. +49 6461 7585 2-10

Fax +49 6461 7585 2-90

f.dehnert@fkm.email

www.fkm.net

Since 2005, kuhn-stoff Gmbh & Co has exclusively specialized in designing and producing additively manufactured parts from polyamide, primarily serving customers from the field of specialized mechanical engineering. EOS e-manufacturing is a living reality for kuhn-stoff, who are leading providers in using additively manufactured parts as end products.

kuhn-stoff GmbH & Co KG

Drosselweg 1

88250 Weingarten

Germany

Contact:

Hannes Kuhn

Tel. +49 751 5612 898

Fax +49 751 5688 943

info@kuhn-stoff.de

www.kuhn-stoff.de

Materials Solutions is a provider of high-temperature applications in the fields of application development and material development, such as for aircraft engines. Materials Solutions owns five EOSINT M 270 metal laser sintering systems, as well as a machine hall, sandblasting equipment, heat treatment furnaces, an acceptance room with a GOM scanner, and coordinate measuring facilities. They also offer microscopy with scanning electron microscopes and a chemical analysis laboratory. In addition, Materials Solutions develops process parameters and manufacturing methods for customers and contract manufacturers working with parts made from cobalt-chrome, nickel-based superalloys and stainless steel. Materials Solutions is a qualified supplier for a wide range of customers and is approved under AS9100 Rev C.

Materials Solutions

Unit 8, Great Western Business Park

McKenzie Way

Worcester, WR4 9GN

United Kingdom

Contact:

Carl Brancher

Tel. +44 1905 7321 60

Fax +44 1905 5302 24

info@materialssolutions.co.uk

www.materialssolutions.co.uk

PRODINTEC was founded in 2004 as a non-profit technology center in northern Spain. Its primary activities include research and development, as well as innovation projects related to advanced manufacturing technologies, product design and construction. PRODINTEC supports companies in all areas of additive manufacturing and offers integrated, innovative solutions ranging from 3D scanning to series production, including the use of state-of-the-art software for additive manufacturing, quality control and post-processing. To date, the company has completed more than 2,000 service orders and 30 research and development projects in additive manufacturing across various industries and applications, such as housing for electronic devices, medical implants, aerospace applications, automotive parts, cooling channels, and small molds.

PRODINTEC

Parque Científico Tecnológico de Gijón

Avda. Jardín Botánico, 1345

33203 Gijón

Spain

Contact:

Iñigo Felgueroso

Tel.: +34 984 390 060

Fax: +34 984 390 061

info@prodintec.com

www.prodintec.es

The Innovative Product Development Center (IPDC) of Wolverhampton University* was founded in 2002. The IPDC is the ideal partner if you want to evaluate how you can design your products to be convincingly attractive – whether for existing markets or new ones. The IPDC is currently working with two additive manufacturing systems and can quickly make your ideas a reality.

Wolverhampton University

Innovative Product Development Centre

Wulfruna Street

Wolverhampton

WV1 1LY

United Kingdom

Contact:

www.wlv.ac.uk