Metal 3D Printing - The DMLS Technology How Does it Work in Detail?

With DMLS it is possible to create 3D printed metal parts directly from a computer model. The main ingredient to create such a part is a powder of a metal alloy. The technology is used for industrial 3D printing.

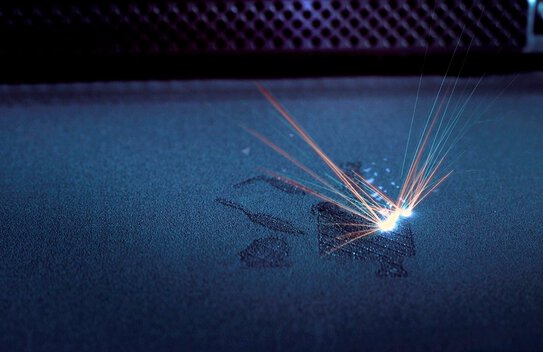

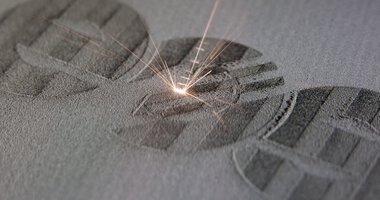

In the metal 3D printer, an ultra-fine layer of the metal powder is spread across the building platform. Then, a powerful laser in the 3D printer melts the powder exactly at the points defined by the CAD model. In this way, one layer of the 3D printed part is completed. This procedure repeats until the part is completed:

Three steps of the DMLS technology

- The 3D printer continues to spread layer by layer of the metal material

- The laser precisely melts the desired shape in each layer

- The 3D printed part grows layer by layer.

What is Metal Additive Manufacturing?

The DMLS technology, as used by EOS metal 3D printers, follows the principle of - in German - "Direkt Metall Laser Schmelzen" (DMLS, Englisch translation Direct Metal Laser Melting). It is a Laser Powder Bed Fusion, or short LPBF technology, and stands for one of the world's most advanced and reliable technologies in metal additive manufacturing. This high-end 3D printing technology is used for serial manufacturing of (industrial) 3D printed metal parts for a wide range of industries. The main applications are aerospace, automotive, medical, tool and turbomachinery. EOS is the leading global provider for industrial metal 3D printer and has been using the DMLS technology for almost three decades.

Spotlight on Quality with EOS Metal 3D Printing Experience in Additive Production since 1989

Metal 3D Printer DMLS systems for every need

Reliable production for many customers around the world: Are you looking for the right metal 3D printer for your parts production? EOS offers additive manufacturing machines with proven DMLS quality – perfectly suited to your individual manufacturing requirements.

The workhorse in metal additive manufacturing, the mid-sized 3D printer EOS M 290 with the widest range of metal materials offers you the perfect package for high-quality parts.

To manufacture delicate metal components e.g. for medical applications our EOS M 290 is the 3D printer of choice.

For serial production of additive manufactured metal parts, we offer flexible and highly productive 3d printing solutions: powerful big volume metal 3D printer for large metal parts and ultra-fast four-laser systems for an efficient production of high-quality serial parts.

DMLS Materials for Metal 3D Printers

To ensure a high quality of your part, it is important to use a high-end material for the metal 3D printer. EOS offers a wide range of high tech materials designed specifically for metal 3D printing using our DMLS technology. Depending on the need of your individual production you can choose an alloy from our DMLS material portfolio. That could be aluminium, cobalt- chrome, nickel-based, refractive metal, stainless steels, tool steels, case-hardening steels, copper, and titanium alloys as well as precious metals like gold.

The use of titanium as the material for the retaining brackets of our satellites has proven highly effective. The main weakness, however, was the connection of the brackets with the carbon panel of feed and reflector assembly because here the thermal stress was a negative factor. Thanks to Additive Manufacturing, we were able to redesign the bracket and eliminate this vulnerability. There were other benefits, too, such as shorter, more cost-effective and more lightweight production.

Solid. Reliable. Flexible. How our customers are successful with our 3D Printers

Our DMLS technology is being used for wide range of industries such as aerospace, automotive, medical, tool and turbomachinery. See some of our references.