10 Key Skills for Industrial 3D Printing

With higher education institutions just now beginning to integrate AM instruction into their curriculums, organizations beginning to leverage AM have found themselves relying on third-party organizations to educate their internal engineering teams. Luckily, the EOS Additive Minds consulting team is one of those third-party organizations and is here to help from start-to-part along your AM journey.

The Levels of 3D Printing Expertise

Industrial 3D printing can have an extensive learning curve, but can be broken down into levels or phases of AM technology throughout your 3D printing education journey:

Level 1: The additive manufacturing basics

Level 2: How to select the right applications for your production

Level 3: AM design and engineering

Level 4: Scaling and validating production

The Additive Minds Academy, also known as the education arm of Additive Minds consulting, provides in-depth courses covering each of these levels for your engineering teams. Built by AM engineers for future AM engineers, these courses are meant to get your team up to speed and stay up to speed for all your additive manufacturing needs.

Key Skills

1. Understanding the process

AM is a process, not a button. As much as we admire our 3D printer’s abilities to start and build on command, the educational portion of industrial 3D printing is not that simple. Here are a few of the phases throughout the AM production journey:

2. Designing for 3D printing

Design is one of the most important parts of the AM process. Without useful design, every other stage is unpredictable. An educated and creative AM designer can decrease the amount of wasted powder, longer build times, and lower overall cost-per-part, making them a vital part of the team.

3. Managing the system and application engineering software

To create a great application, you need to master both the system and software at play. To select the right quality part parameters for each case, you need to understand what these part parameters mean for your application performance, and what results will come from changing process parameters like up-skin, core, down-skin, overlapping, and contours.

4. Selecting the right material

Each material has its unique properties and will behave differently throughout the AM process. Therefore, you need material-specific parameter training to understand the values and implications of different material selections. Exposure settings for hatch, contour, and edge effects are vital to a successful application as well.

Material selection also applies to your application performance, finding the right material to fit your desired application capabilities. It is important to know which materials shrink, warp, or deviate when processed and exposed to varying environments.

5. Preparing for the build

Understanding the data preparation process will enable you to optimize job preparation and reduce failed builds, saving you both time and money on the production floor. Learning how to design successful support structures, how to choose appropriate materials, and how to select the most beneficial parameters for each application type does not come naturally – no matter how easy AM experts may make it seem from an outside perspective.

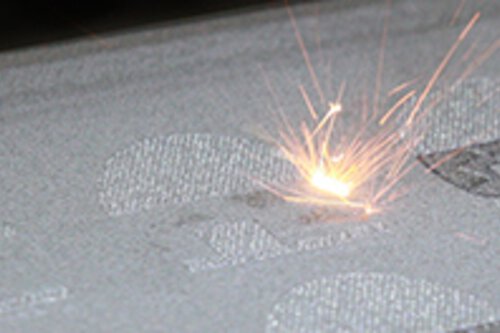

6. Operating the AM system

Before you can operate a system, you need extensive training on the safe and efficient operation of the machine itself and its peripherals. This includes the handling of the processing software, the set-up, job start, and observation of the process.

7. Post-processing and surface finishing

Additive manufacturing is not only about designing and preparing your project for 3D printing, but knowing how to make it shine after the build is successful as well. A distinguished, professional feature of an AM application is the level of post-processing used to smooth, shine, and finalize the part.

8. Defining the desired quality

Recognizing the definition of quality within the 3D printing industry and how to measure it throughout the AM process is another element of becoming an established 3D printing engineer. To truly benefit from the use of industrial 3D printing, you should be able to identify the quality criteria such as dimensional accuracy, tensile strength, hardness, density, and electrical conductivity in your application.

9. Developing skills for business

Finally, learning how to properly carry out a business case analysis is a key step of the AM journey. This presents the opportunity to show off your knowledge of the entire process chain, and successfully guide your organization while leveraging AM. Getting to know the impact of key cost levers and how to reduce overall cost-per-part is an integral part of preparing yourself and your business for future AM projects, as well as understanding both the quantitative and qualitative types of business models.

10. Distributing production

Before you start serial production, you should simulate your production using a digital twin. As a result, you can forecast the throughput and output of your production site based on the machine parking equipment, operator shifts, machine maintenance procedures, etc.

Since the entire process chain from procurement to production is digitally synchronized and all machines are connected and communicate via IIoT platforms, you can easily align your production with local demands while significantly reducing transportation and storage costs.

How to learn more and grow your expertise with the Additive Minds Academy

Whether you are a professional seeking further development, or a business and innovation leader seeking new talent to take advantage of AM, training your workforce for industrial 3D printing is necessary.

The Additive Minds Academy has developed a comprehensive online training program to optimize the onboarding process of your internal engineering team and accelerate knowledge buildup while being at the forefront of innovation. The portfolio consists of online courses and e-learnings for all levels of expertise, making additive manufacturing knowledge available anytime, anywhere.

Find the 3D printing solution that best fits your manufacturing needs.

Learn More

Master the critical steps to successfully implement polymer 3D printing into your business.

LEARN MORE