A Holistic Approach for Cost Analysis in Industrial 3D Printing

Additive Manufacturing Cost and Carbon Calculator

Most Manufacturers are cost-conscious and understand the mounting importance of sustainability. Additive manufacturing helps address both issues: It's cost-effective when strategically implemented, and it's more sustainable when carefully designed with emissions and waste in mind.

Feedback from EOS customers highlighted some specific cost analysis concerns: For example, we commonly heard that cost-per-part (CPP) was too high for large-scale production in regulated industries. Feedback like this — as well as our commitment to enabling responsible manufacturing — spurred our Additive Minds consulting team to develop a powerful cost and sustainability analysis solution.

Key features and benefits

The EOS Cost & Carbon Calculator helps manufacturers uncover and assess all notable factors driving CPP and other cost-related key performance indicators (KPIs) and can also calculate the emissions from various greenhouse gases (CO2 equivalents).

- It provides a transparent overview of CPP from machines, materials, post-processing steps, consumables and other overhead costs.

- You can roughly estimate CPP for metal or polymer parts based on EOS-collected data, or calculate at a 95% accuracy rate via simulation if you provide data from EOSPRINT, Magics or another software solutions from EOS.

- Detailed visualizations display primary CPP data in pie chart and bar graph formats.

- The calculator also dives deeper with more granular data: top variables driving CPP (e.g., part volume, build rate and material price), sensitivity analysis (how broad correlations between CPP and key variables increase or decrease) and cost matrices (to identify precisely how you'd need to adjust impact variables to reach a target CPP).

- For CO2e analysis, the calculator provides heat map visualizations that identify emissions sources from specific materials or applications and illustrate the costs stemming from these emissions. Furthermore, it offers prescriptive recommendations on how to reduce emissions based on your organization's specific situation.

- All of this data is neatly summarized in generatable reports, which you can save to your device or in the cloud for future reference (and edit if necessary).

The EOS Cost & Carbon Calculator addresses the big picture by serving a bottom-line need: accurate analysis of CPP and critically important related metrics. At the same time, users of the calculator should rest assured that the tool accounts for the many different factors that influence costs either positively or negatively, no matter how common or niche their use may be.

Calculating for CO2 equivalents (CO2e)

While putting the EOS Cost & Carbon calculator together, the Additive Minds team realized the tool could easily measure 3D printers' use of key resources. This information supplied the variables necessary to solve for various greenhouse gas (GHG) emission formulas and determine the specific sources of CO2e emissions for individual AM-tooled parts.

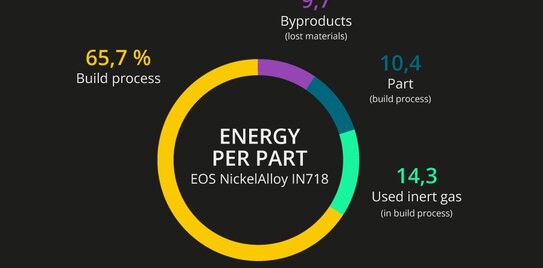

For example, we can determine that the build process accounts for the majority of energy consumption in the below sample example for a part tooled on a metal 3D printer using EOS NickelAlloy IN718, as follows:

This information also informs EOS' work on new systems, materials and solutions that will make additive manufacturing more sustainable in the future. The EOS Cost & Carbon Calculator projected that an exposure technology still in development has the potential to notably lower energy consumption per part by about 20%.

Driving sustainable strategies

The EOS Cost & Carbon Calculator is steadily being improved by Additive Minds: We work hard on measuring internal data and obtaining as much external data as possible from third-party partners. Understanding the exact breakdown of your organization's additive manufacturing costs serves as an efficient route to actionable insights.

Knowing CPP, CO2e and other key metrics is a firm foundation upon which to build concrete plans to change processes that are wasteful and/or unsustainable — and maintain or improve operations with favorable KPIs. For example, if the calculator identifies the laser powder bed fusion system as a key area around which to focus, it will also reveal opportunities to increase energy efficiency by illuminating multiple potential courses of action: You could switch to carbon-neutral materials for certain builds, use less carbon-intensive methods elsewhere in the life cycle or change part design parameters, to name just a few possibilities. To supplement the calculator's recommendations, our Additive minds experts can consult with you regarding CPP and emissions analytics to help you identify the most sensible options for your situation.

Sustainability's mounting importance is far from a flash in the pan: In fact, government and industry regulations regarding CO2 and other GHG emissions are likely to tighten in the years to come, and manufacturers will further adjust their practices to account for this.

Authors: Nameer Syed, Senior Additive Minds Consultant of EOS &

Lea Stegemann, Sustainability Manager of EOS