Finding a Certified Partner to Scale with Additive Manufacturing in Europe

Why a certified AM supply chain for your production matters

Bringing products to life at scale can be a demanding experience. Particularly if a company works in a certified industry or requires high-volume production that does not compromise on the quality of the final product, or global distribution. Once the right solution is identified, our customers often pose the question to us whether to manufacture themselves and to set-up a 3D-printing production site or whether to find a manufacturing partner so that they can buy the final part. This make or buy question has been posed to us very often. Thus, we have identified a strong need in the market to be able to find the right manufacturing partner.

We at EOS do not only enable companies to identify the best application and technology framework. We also consult customers on in-house versus external production. We run a dedicated process and if a third-party production partner is the best choice, then we advise EOS certified production partners where they can be sure to receive the quality of parts that they would expect.

To have a perfect match for our customers' applications we installed two manufacturing partner categories in EMEA.

Contract Manufacturing Network

If you are looking for a supplier to manufacture a specific part in a series production the EOS Contract Manufacturing Network is the right choice for you. The database will grow to approx. 20 partners around Europe that offer additive manufacturing using EOS systems, processes and materials based on the latest technology.

End-to-End Production Partner

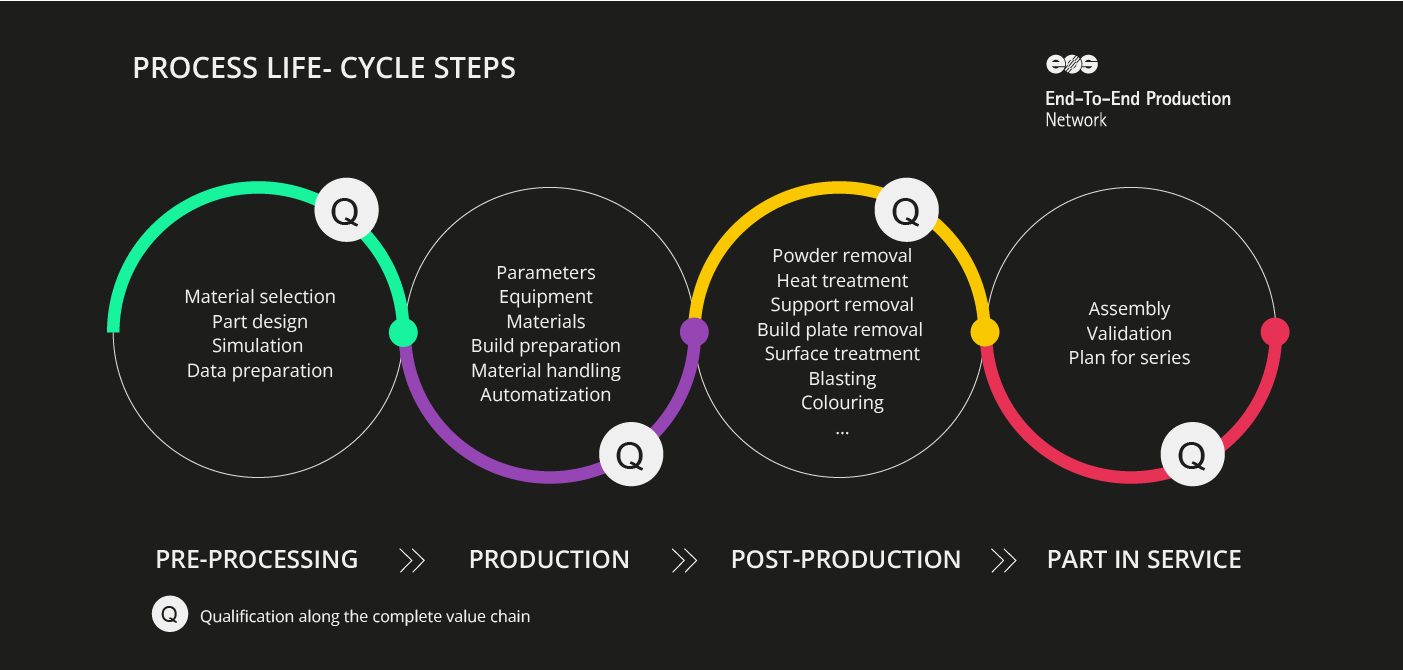

You now might be wondering what the difference is to an end-to-end production partner. When our customers need a partner that is solidly positioned and can produce high-quality 3D-printed parts in mass series production, they are looking for a partner that can create the right product and also have the experience needed to bring products to the market. This includes not only the right part selection, but also AM-specific part design as well as competencies in sub-assembly. The partners have a fully qualified and optimized EOS branded solution to optimize the production.

Finding the right partner for end-to-end serial production in Europe

To become a network partner, companies undergo a certification process where the end-to-end capabilities are the key criteria. From part design to design optimization for AM, manufacturing capabilities, pre- and post-processing including surface treatment, all the way to quality assurance and assembly to create high-end final parts in series.

Offering end-to-end capabilities

Our two partners within the EOS end-to-end production network so far are MT Aerospace and Prototal. MT Aerospace is based in Germany and a leader in lightweight structures made from metal and composites with a focus on the aerospace industry.

Prototal’s value proposition for you

Prototal is Northern Europe’s biggest supplier in industrial 3D printing, vacuum casting, aluminum tools, and injection molding. The Swedish company has been an EOS customer over 20 years and offers end-to-end additive manufacturing capabilities for large scale serial production and to demanding and highly regulated industries such as aerospace, medical or automotive, to name a few. The value proposition includes digitalization and automation in both software and hardware, combined with over 400 experienced and competent employees.

Prototal provides you with:

-

More than 85 professional AM systems. 50 of them are EOS systems for polymer 3D printing. Prototal’s machine park also contains over 120 injection molding machines.

-

Digital additive manufacturing factories in Sweden, Norway, Denmark, UK, Italy and Austria.

-

Comprehensive quality assurance, certified to ISO 9001, ISO 14001, ISO 13485 and AS/EN 9100.

-

A large portfolio of AM materials including PP, PA1101, PA2200, PA2210, PA3200, Alumide, PA603-CF, Rubber 50A-80A, PA12, PA12GB, PA12W, TPU88A, TPU95A, ClearVue, Xtreme Grey.

-

A commitment to responsible manufacturing, e.g. Prototal processes the high-performance polyamide PA 1101, which is made from 100% renewable castor beans

Author: Dietmar Frank