Additive Part Manufacturing for Turbomachinery 3D Printing for Gas Turbines & More

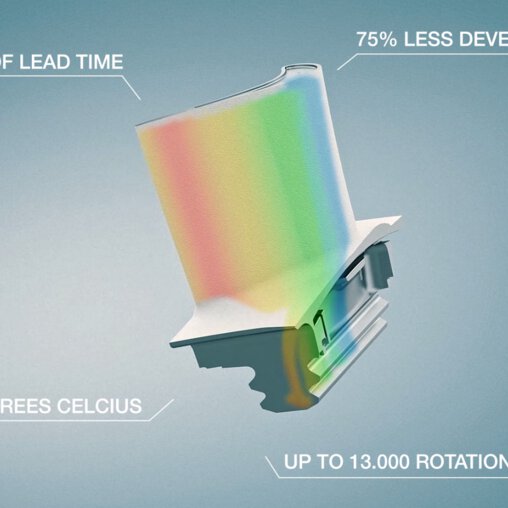

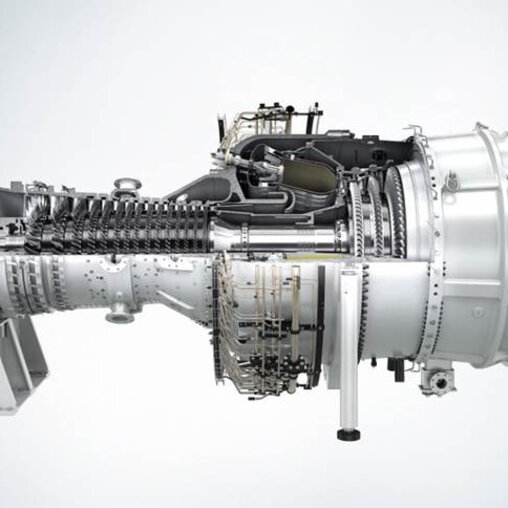

Turbomachinery is indispensable for energy generation. Its high-performance parts feature complex, high-tech designs that need to be more and more robust and powerful as the demand for energy increases. In addition, turbomachinery parts need to be resistant and reliable – even at temperatures beyond the melting point.

Additive manufacturing can solve many of these challenges and is suitable for numerous applications:

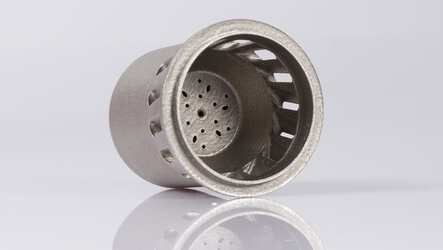

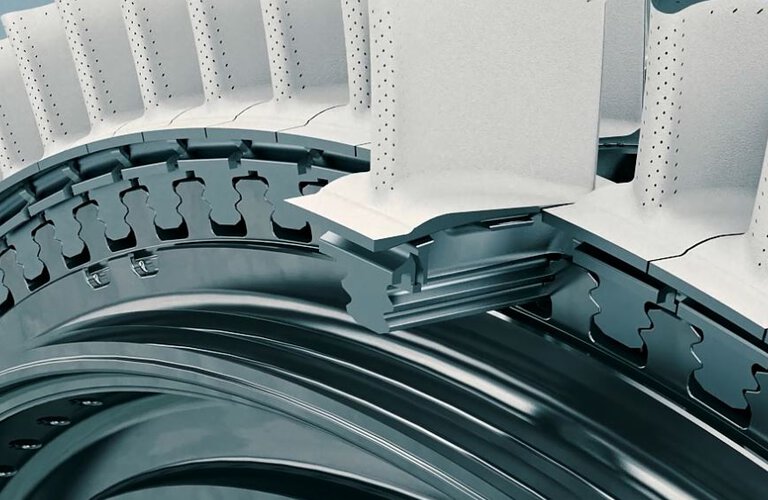

blades and vanes, fuel injectors, impellers, swirlers, burners and combustion chambers, cladding, seals, housings, and much more. The 3D metal printing process (DMLS) offers the right technological foundations for implementing an optimized cooling strategy, among other things. Parts can be designed and made to transport and apply energy with increasingly precise focus. Innovative repair processes, for example, are revolutionizing the efficiency of turbomachinery parts by building at worn areas directly on the original part.

Improved performance and efficiency

Drastically reduced lead time

In-sourcing of IP and manufacturing capacity: less dependency

The collaboration between Siemens, Material Solutions and EOS demonstrates that 3D metal printing is a reliable and proven technology viable even for “moving” applications, without any compromise. In focus: developing a new turbine blade. The part was developed together with Siemens NX, built on EOS systems and produced by Material Solutions.

Want to find out more? Get in touch!

Siemens relies on an EOS system to manufacture burner fronts featuring functional integration – redesigned with Siemens NX and manufactured in series on an EOS M 400-4 from EOS NickelAlloy HX.

Industrial 3D Printing for Manufacturing Burners More Success Stories From Our Customers

Optimized Maintenance Management Based on 3D Printing

Downtime caused by repairs and maintenance work is a huge cost factor in large-scale energy generation plants. Especially for parts with high complexity and integrated channels, the hybrid repair process based on direct metal laser sintering (DMLS) opens up unique opportunities to save time and costs. How does it work? Areas that experience wear are reconstructed directly on the original part.

This has far-reaching advantages:

- No additional welding steps are required

- Improved quality of the connection between the reconstructed area and the original part

- The alignment of internal structures is preserved

A Demanding Task and a Smart Solution

Thanks to a customized EOS system, Siemens found success with a precise and fast maintenance process for burner tips subject to high thermal stress in gas turbines. The repairs are performed by building directly onto the worn material, saving time and cost.

Everything You Need for Turbomachinery Parts From a Single Source

We offer robust systems with repeatable part quality and a wide portfolio of materials, capable of handling diverse applications, including those involving high temperatures. To complement this, we also offer tools and software for comprehensive quality monitoring and a consulting department to take care of your needs.