What Drives Manufacturers in the Automotive Industry

The advent of the automotive age was the very definition of disruption, suddenly, muscle power was no longer the only way to achieve locomotion, it could also be motorized. The automotive revolution happened over a century ago, but today the industry is facing a wave of new possibilities and challenges.

Additive Manufacturing for Vehicle Parts Automotive Production With EOS 3D Printing Solutions

Our projects show how customers from the automotive industry have successfully broken new ground with EOS solutions. Our solution chains for industrial 3D printing allow potential to be leveraged and products to be reimagined where classical technologies could not meet this need. Together with well-known companies from the vehicle manufacturing and motor sports sectors, we tackle a wide variety of challenges with great success for our customers.

Made With EOS Product Innovations by Our Customers

EOS Projects From Practice Additive Manufacturing for the Series Production of Vehicles

For automotive manufacturers and suppliers, additive manufacturing is more than just rapid prototyping: from spare parts production on demand to series customizing and automated 3D production cells for industrial manufacturing, anything is possible. In this area, 3D printing is especially effective thanks to its combination of flexibility, innovative strength, and cost-efficiency.

An overview of our projects

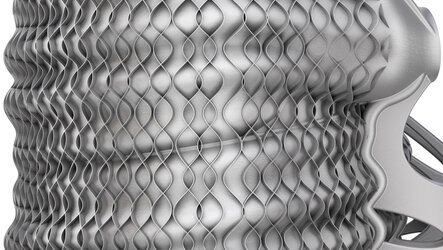

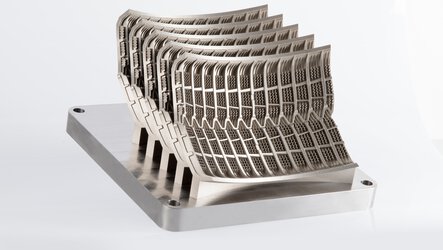

Heat exchangers for more efficiency, optimized spare parts logistics on demand or the series production of complex parts for various models of automobile: over the past 30 years, we have realized many innovative projects together with well-known automotive manufactures and suppliers.

EOS Projects From Practice Additive Manufacturing in Motor Sports

Motor sports have been the cradle of many groundbreaking technological developments, due to the high requirements of innovation and security, additive manufacturing has played a major role in this field. No other manufacturing technology allows you to think this far out of the box, when bringing your ideas to the racetrack.

Successful projects

The motto in motor sports: everything matters. Every gram of weight and every tiny increase in performance is extremely important for the overall system. This for example, is reflected in the design of a battery container with integrated cooling channels by Formula Student and the 3D-printing-based production system at Pankl Racing Systems.