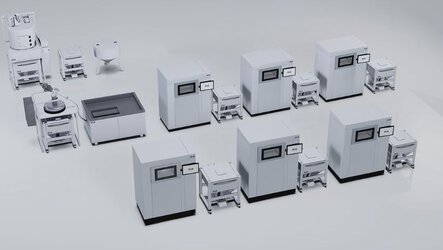

Improve the Workflow, Reduce the Costs Flexible and Efficient Conveying and Sieving of Plastics

To meet the diverse requirements of our customers, the three product solutions have different degrees of automation, suitable for small, medium and large volumes of material. They are compatible with all EOS systems for additive manufacturing with plastic, can be flexibly integrated into the production environment and enable the reliable production of parts. Material management unfolds in parallel to the build job, which reduces the set-up time between build orders and therefore increases the overall productivity. The simple mode of operation and high safety levels minimize the risk of powder contact for operators. Sampling for quality assurance purposes is possible at any time.

Cost-Efficient & Easy Manual Solution Specially Designed for Development Environments

This cost-effective manual solution can be operated with multiple machines and is ideally suited to development environments. Changing the material is quick and easy, which means that the solution can be used flexibly with different materials.

The Components of the Manual Material Handling Solution

Semi-Automated and Versatile The Standard Solution IPCM P

The IPCM P is a semi-automated solution for quick and safe powder handling. It offers an attractive price-performance ratio and is ideally suited for being used with several machines. Last but not least: operators have significantly less contact with the powder.

The Components of the Standard Solution IPCM P

Fully Automatic With a Closed Powder Cycle Automatic Solution IPCM P plus

With the IPCM P plus, you can transport larger amounts of plastic powder. This fully automatic solution ensures consistently high material quality and serves a variety of systems by precisely dosing, processing, homogenizing and conditioning the powder. The closed powder cycle guarantees the traceability of powder batches.