Digital Factory: Industry 4.0 & Additive Manufacturing Shaping the Manufacturing World of Tomorrow With EOS 3D Printing

You don’t just redesign your manufacturing infrastructure for the sake of it. Redesigning happens in response to the waves of disruption that manufacturers must face, today and tomorrow.

One key aspect is classical production chains, which are designed for permanent utilization and efficiency, with supply chains that feature high goods values and capital investments. This means high costs and little flexibility – in times where there are always new market variations and demands to address.

In some industries, megatrends are another challenge. For example, in the automotive industry, an increasing number of base modules are being used as a starting point for a wide range of custom-designed parts manufactured according to customer wishes. Especially considering the increasing cost pressure, the problems faced by classical manufacturing structures seem almost impossible to solve.

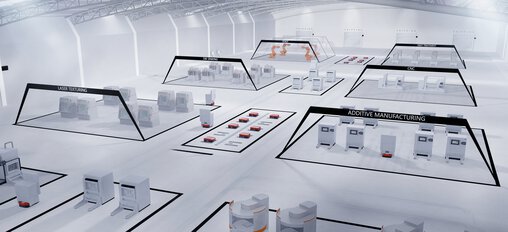

From Concept to Reality The Elements of Automated Additive Manufacturing With EOS Systems

The keyword is process automation. The powder and build platform process is part of the 3D printing technology. Post-processing is then performed after the part is finished. Another step toward the factory of the future production system – EOS is working on various aspects of digital manufacturing cells:

- Automated Guided Vehicles (AGVs) to transport build platforms and other objects between workstations

- Set-up station to prepare the build platform for the build job

- Automatic material provision

- Unpacking station to prepare parts for post-processing

- Container transport mechanism for frames featuring a protective gas atmosphere

- Machines for post-processing and quality assurance customized according to requirements and needs

The EOS Connect ControlCenter connects all of the hardware together.

Hardware in Applications The EOS Shared Modules Concept for Metal Parts

NextGenAM Production Cell We Have Made the Digital Factory Happen

EOS’s collaboration with Premium AEROTEC and Daimler to create a digitally connected pilot system (NextGenAM) demonstrates that this is all more than just a pipe dream. The project has passed the proof-of-concept stage and can now be converted into a series production facility.

The NextGenAM production cells show which components belong to each additive manufacturing cell and what opportunities dynamic and integrated manufacturing can open up in a wide variety of industries.

The successful outcome of NextGenAM over the entire production process at Premium AEROTEC, the production costs were reduced by up to 50%

compared to previous 3D printing systems.

Industry 4.0: Digital Manufacturing Technologies and Processes Integrated and Digitally Networked

The digital factory uses additive manufacturing in combination with regular manufacturing methods and scores high marks in terms of agility and flexibility. For some parts, it reduces manufacturing costs by half, or at the very least achieves a greatly reduced cost per part. It also allows previously impossible parts to be realized – with complex geometries, lightweight designs and high levels of functional integration. This all strengthens the factory’s competitiveness and reduces investment costs in the long term.

Additive manufacturing offers a way to break away from the confines of what is currently possible, a way to reimagine things and make them happen differently: from design to the realization of entire production series within an integrated production facility.