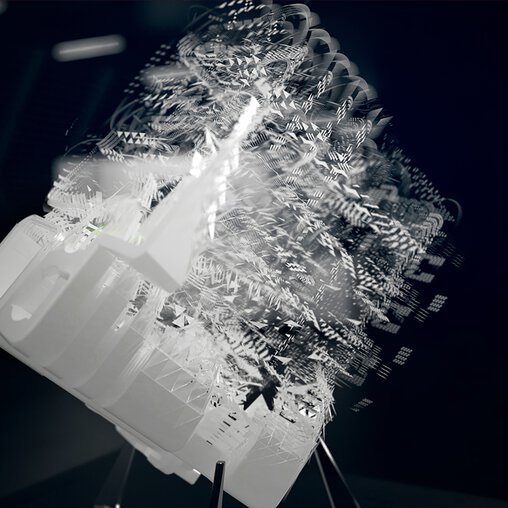

Sharp Laser with Stable Material The Perfect Match for Parts with High Detail Resolution

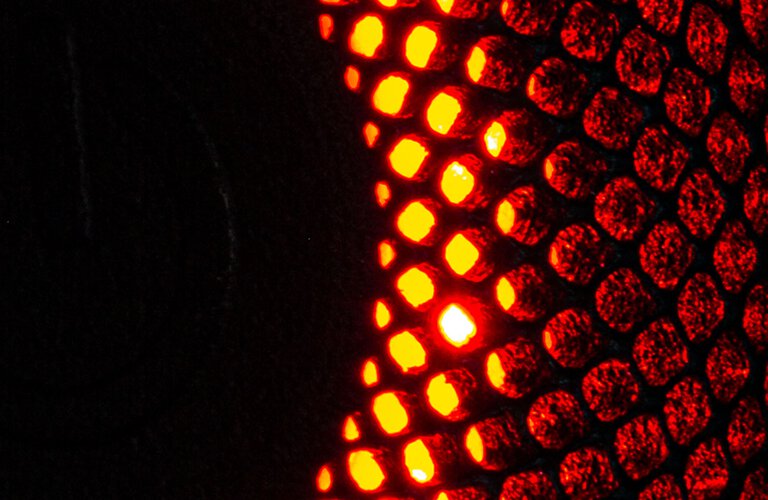

Fine Detail Resolution (FDR) technology is the only solution on the market that enables production of delicate parts without sacrificing quality. The one-of-a-kind laser has an ultra-fine beam half the size of standard SLS systems. Combined with PA 11, a remarkably flexible and lightweight polymer material, produces rigid parts with the finest high-detail resolution.

The new technology combines the best of two worlds: the high detail resolution of stereolithography (SLA) and the durability and quality of powder-based industrial 3D printing (SLS).

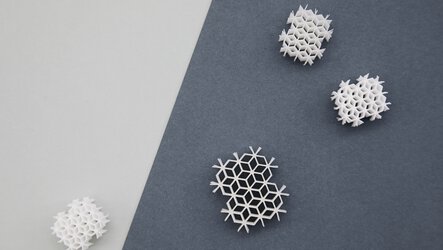

What is it used for? Insight into revolutionary FDR applications

The technology was developed to produce high-precision components to open entirely new product fields manufactured with plastics-based additive manufacturing. Applications range from filter units and fluid guides to electronic components. Additionally, the material is immune to elevated ambient temperatures, which expands the application areas and allows for live operation testing.