More Efficiency in Cost, Functionality and Design 3D Printing in the Electronics Industry

Additive manufacturing offers many advantages to companies in the electronics industry, including faster time to market, the manufacturing of prototypes, pilot and small production series parts, and swiftly implementing customer-specific solutions. Whether you need heat exchangers, housings, communication parts, drones, three-dimensional circuit boards or inductors – the diversity of possible additive manufacturing applications spans the entire industry.

At EOS, we’re ready to support your applications, from machines and peripherals to materials, to consulting services for the successful introduction, implementation and expansion of your additive manufacturing program.

Our portfolio is built upon decades of market experience, expertise with industry-specific topics and collaboration with leading partners.

Technological Opportunities and Success Stories EOS 3D Printing Technology for Electronics Parts

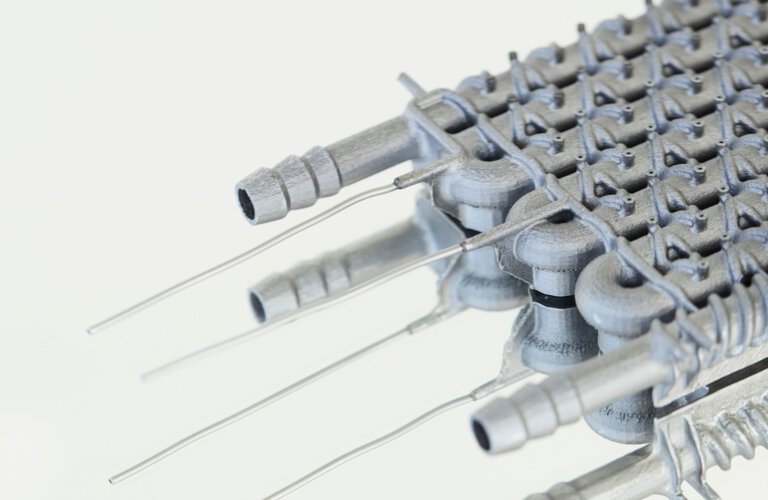

3D Printed Heat Exchangers Optimize the Production and Performance of Cooling Parts

Wherever electricity or heat is flowing, you will typically require a high-performance heat exchanger. Industrial 3D printing is extremely promising for the manufacturing this kind of temperature management part. It allows you to surpass heat transfer limitations and enables very complex geometries and larger surfaces to be realized. Resulting in highly efficient heat transfer with minimal space usage. Additionally, the process is ideal for manufacturing particularly light components within a cost-effective framework.

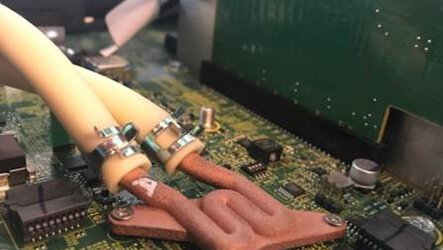

Additively Manufactured Plastic Housings for Electrical Appliances With 3D Printing

Sealing properties, stability and an unlimited diversity of shapes – three of the many advantages of additively manufactured housings. In addition, additive manufacturing can reliably solve challenges like electrical conductivity and we offer materials with useful electrical dissipation properties. Thanks to these advantages and its lean cost structure, additive manufacturing is a profitable alternative to processes based on molds.