Additive Manufacturing for Space Propulsion Satellite Parts, Rocket Engines and More From the 3D Printer

Spacecraft and satellites have always been reliant on new and advanced technologies. Today, it’s 3D printing that is opening up new design and manufacturing opportunities, even for the most relevant parts. An increasing number of young companies are entering the space industry – armed with the knowledge that 3D printing technology is capable of satisfying the strict requirements of the aerospace industry while remaining cost-efficient overall.

Focus on Speed and Efficiency

Especially in the rapidly growing market of commercial space applications, the ability to manufacture prototypes and small series productions plays a decisive role. There are often extreme customer-specific requirements on aerospace parts, which matches up perfectly with the possibilities offered by additive manufacturing.

Additive manufacturing also enables the use of custom materials such as copper alloys that would be very difficult and expensive to process conventionally.

That’s Why EOS Is the Right Partner

For satellite rockets, most companies are looking for a metal-based manufacturing process to produce complex or otherwise difficult parts.

Weather data, communications, global positioning systems, global pictures and maps – a growing number of services are taking advantage of small satellites, or in some cases are completely dependent on them. To put these microsatellites into orbit, small launchers are required. Market demand for these launchers are steadily increasing. Over the past few years, this “New Space” industry has blossomed rapidly with many different start-ups and companies specializing in development. The company that successfully launches the largest payload into space with the most efficient engine will win the race.

Additive manufacturing is the key approach to keeping costs low while maintaining an optimal engine design, but this only works if the engine can be 3D printed as a single piece.

LAUNCHER 3D Printing a Rocket Engine

3D printing offers decisive advantages when building rocket engines. In addition, the functionality of parts can be completely reimagined and reinvented: for example, you can integrate integral cooling channels into a combustion chamber, or consolidate multiple parts into a single all-in-one design.

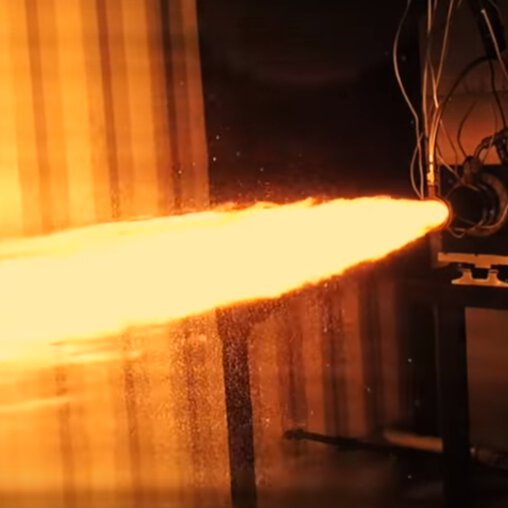

The engine is based on a standard rocket design but is extended with internal ribs for optimal cooling. LAUNCHER successfully constructed, tested and further developed this new design quickly and cost-efficiently, entirely thanks to 3D printing.

The World’s Largest Single-Piece 3D Printed Rocket Engine

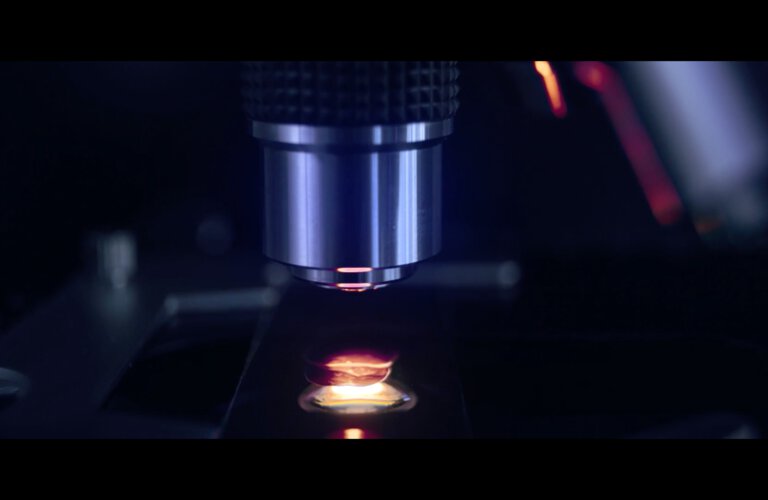

The obstacles included the size of the build space and the difficult material properties. AMCM, a company in the EOS group that offers specialized machines tailored to customer requirements, accepted this challenge.

The chamber is 86 cm (34 in) high, with an outlet nozzle diameter of 41 cm (16 in).

The booster recently won a $1.5 million prize at the US Air Force Space Pitch Day, which was held to accelerate the development and testing program of the E-2 booster. The first large-scale test runs have already been planned.

The animation shows the full combustion chamber with additively and conventionally manufactured parts.

Traditionally, manufacturing this type of part requires millions of dollars of investment in custom machines. Now, with 3D printing there is the option to print the combustion chamber, nozzle and neck combined into a single piece. Thanks to this progress, our work is easier than ever before.

EOS Innovation Story Injection Head for Ariane 6 Rocket Engines

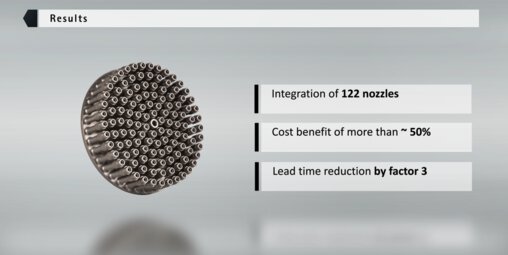

To produce their new Ariane 6 rocket booster, the ArianeGroup decided to manufacture a mission-critical engine component themselves using industrial 3D printing. The key objective was to reduce the original 248 individual parts as much as possible, while also reducing the unit costs.

The EOS Additive Minds team and the Ariane team tackled this challenge together: after risk and scenario analysis and an estimate of the overall costs, the cost per part was optimized. Next, the production layout was created and visualized, and the production flow was planned and optimized.

Watch the video below to find out more.

The Ariane program combines our innovative strength with the expertise of EOS. Together, we are preparing to additively manufacture the injection head for a rocket engine. The results are impressive – a significantly reduced production time and a 50 % reduction in costs.

EOS Innovation Story Topology-Optimized Antenna Mount by RUAG

Additively manufactured parts are becoming increasingly common on and in satellites that are launched into space. The technology meets all of the critical requirements: parts are needed in low quantities and they achieve weight and cost reductions through material savings, which is crucial.

For example, the topology-optimized and additively manufactured RUAG antenna mount for the Sentinel satellite is lightweight and extremely stable, made from EOS Aluminium AlSi10Mg on the EOS M 400 system.

In a certain sense, we’re squaring the circle: We successfully made our part considerably lighter and yet much more stable. The properties were demonstrated with hard test runs, which is essential in the aerospace industry. We’ll be hearing a lot more about additive manufacturing in this industry over the next few years – without a doubt!

Key Figures

Success Story Sky-High Productivity: EOS and Senior PLC Collaboration Accelerates 3D Printing for Aerospace

Challenge:

Quickly automate and optimize material handling.

Solution:

Implement a materials management system that could meet the high-volume production demands.

Results:

-

Speed and safety improvements were employed to streamline AM workflow.

-

All manual material handling from production workflow was eliminated.

-

Trained staff supported the new technology, enabling the automated system to flourish.

-

Cost and weight savings of additive manufactured parts were as much as 50%.

Still have questions? We’d be happy to advise you about custom production solutions.