-

3D Printer & Titanium

3D Printer & TitaniumAdditive Manufacturing for Medical Applications

No Risk, Simply ProductionEnabled with EOS M 290 and EOS Titanium

Join the webinar

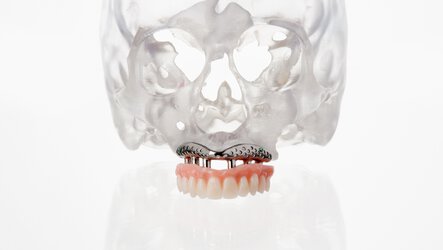

The perfect fit for your production Medical Applications produced with EOS M 290 and Titanium

Reliable production for many customers around the world: The workhorse in metal additive manufacturing, the EOS M 290 together with our titanium materials, offers you the perfect package for high-quality implants. Extensive data on machine and lattice capability, powder reuse and material quality assurance proves it.

Learn more! Register now for our free on-demand webinar

No Risk, Simply Production | 6 Sigma Capability in Metal Additive Manufacturing

This webinar will give you insights into the capability of the DMLS technology – specifically the EOS M 290 – for serial production of titanium implants.

Critical to Quality: Quality Assurance and Key Process Parameters of systems, materials and processes which is the foundation for mass production.

Machine Capability of EOS M 290: Data and statistics for key part properties that show at least a Four Sigma capability – tensile properties even Six Sigma – unique in metal additive manufacturing.

Support-free Hip Stems: HIP-treatment optimized for additive manufacturing plus fatigue properties as good as forged - a first for additive manufactured implants!