Additive Manufacturing Enables the Profitable Production of Individual Pieces in Small and Medium Batches.

3D printing brings economic benefits to the industrial manufacturing chain in two main categories: supply chain and design optimization. 3D printing technology for additive manufacturing exploits potential in areas such as

- Faster time to market

- Reduced weight and assembly times

- Simple product customizations and advantageous High mix-low volume productions

are the key drivers of cost-efficient production with 3D printing.

Discover how and where you can optimize your production with additive manufacturing, reduce your costs and build a sustainable foundation for the future.

Cost-Efficient Production With 3D Printing Don’t Assemble Your Products, Print Them

Produce complex components in the shortest possible time

Industrial 3D printing enables individual pieces to be produced profitably in small and medium batches. Compared to conventional manufacturing processes such as milling, turning or casting, the production costs are not dependent on the complexity of the component. Where expensive tools or complex specialized solutions were previously necessary, potentially representing a risk factor for completion on schedule, a 3D printer and powder material are now the only prerequisites for trouble-free production.

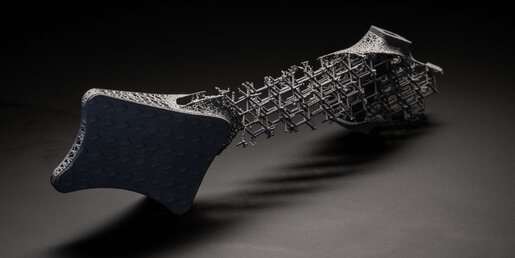

Save material and weight with integrated functionality

With additive manufacturing, the external geometry is almost exclusively the determining cost factor, complexity plays a minor role in production times and costs. Material and weight can also be saved by designing lightweight structures. Intelligently integrated functionality, for example with springs or hinge joints, reduces the number of components and administrative costs in ERP systems as well as the assembly costs.

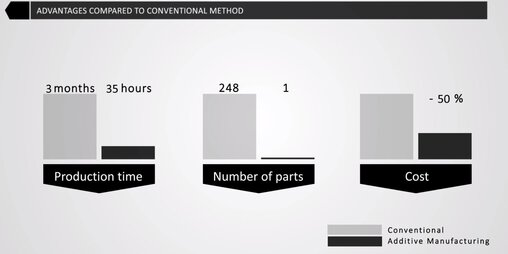

The Key Figures

Manufacturing an injection head for the Ariane 6 engine with additive manufacturing: thanks to the EOS M 400-4, an assembly of over 200 individual parts were transformed into a single component.

- Quicker: the production time was reduced from 3 months to 35 hours

- Simplified: one single component instead of 248 individual parts

- Cost-efficient: costs reduced by 50 %

The Ariane program combines our innovative strength with the expertise of EOS. Together, we are preparing to additively manufacture the injection head for a rocket engine. The results are impressive a significantly reduced production time and a 50 % reduction in costs.

Cost-Efficient Production With 3D Printing Develop and Produce Faster With Additive Manufacturing

Quicker time-to-market

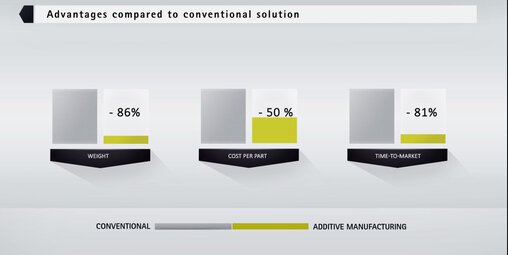

Component adaptations can already be implemented digitally and physically during the product development phase by adapting the 3D data. The time-to-market is sharply reduced as pre-production prototypes can easily be created and optimized. Comprehensive functional integration can be “designed” directly into the component, and complicated structures can be built without tools while reducing sub-components to a minimum. This also considerably reduces the number of development cycles and allows sustainable product innovations to be produced quickly and at a lower cost.

The Key Figures

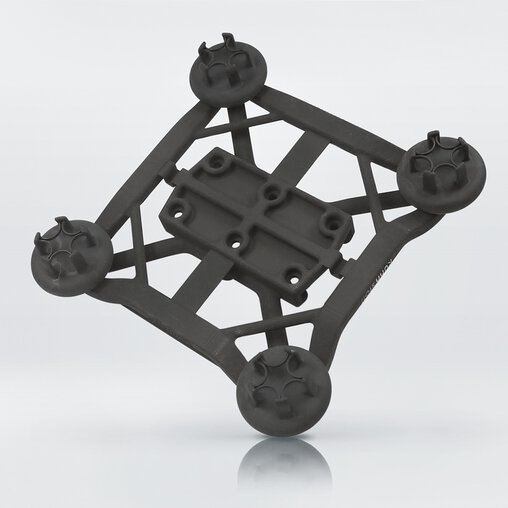

After design simplification, stable grippers were successfully manufactured on a functional plate with FORMIGA P 100 in a small production series.

- 50 % lower production costs

- 3 days of production time instead of 12

- Weight reduced by 86 % to 220 grams

- 2 components instead of 21, leading to lower assembly costs

High Mix-Low Volume Production Individual, Short-Term, Cost-Efficient Without Sacrificing Quality

Implement customizations simply and efficiently

Industrial 3D printing systems by EOS help you to respond quickly to the demands of volatile markets and tackle trends such as the increasing customization of end products. The tool-free 3D printing process of additive manufacturing enables complex components to be produced swiftly, precisely and cost-effectively right down to a batch size of 1 in high mix-low volume production. To achieve a higher product mix with fixed production volumes, you need flexible production technology. With additively manufacturing technology, this is now conceivable and economically feasible.

Ford uses EOS 3D printing to unite the need for security with the desire for customization. Together with the Additive Minds Consulting team, Ford succeeded in creating an innovative application for optimal protection against theft: customized, 3D printed wheel locks. The locks have a special shaft geometry that prevents unauthorized persons from removing the tires and/or rims.

Spare Parts On Demand Revolutionize Your Spare Parts Management!

The 3D printing of spare parts is a profitable investment for many organizations. Storage and transport costs are significant cost drivers and can be avoided by producing spare parts “on-demand”. Manufacturing small batch sizes is extremely time-consuming with traditional production methods. Additive manufacturing is also a valuable alternative when highly-complex components, replacements for original parts that are no longer being made or components for special machines are needed.