The new EOS process control solution includes first-of-its-kind, real-time intelligent heat management reducing or eliminating support structures and performing 2x-5x faster than other technologies.

Smart Fusion is the latest addition to EOS commitment to advancing and promoting metal additive manufacturing (AM) through innovative solutions that simplify the process, save costs and increase productivity.

How Smart Fusion is changing your manufacturing process

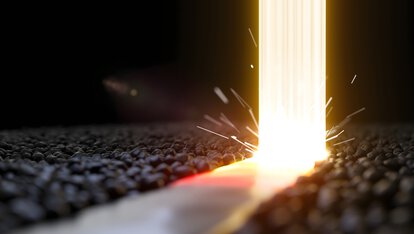

Smart Fusion's real-time capability automatically adjusts laser power to address potential manufacturing issues quickly and efficiently. The technology measures the laser energy absorbed by the powder bed and adjusts it using advanced algorithms. As a positive side effect, support structures can be avoided or even eliminated. This not only saves time, but also lowers your cost per part (CPP) through reduced post-processing and reduced material usage.

This novel software solution enables, more applications a positive business case for AM metal applications, especially for companies with highly technical applications such as energy, space technology, mobility, and aerospace. At its core, Smart Fusion pairs with EOS existing monitoring solutions and employs advanced algorithms to monitor the build layer-by-layer providing for more homogeneous, consistent parts. From a dataflow perspective, EOSPRINT prepares the data, which is sent to the 3D printer, Smart Fusion works with its Optical Tomography (OT) camera whereby the generated images adjust the laser.

Key Benefits

Freedom of Design

Shorter time to market

Reduction of cost-per-part

Working Principle of Smart Fusion:

EOSTATE Exposure OT is used to monitor the thermal behavior of parts in each layer. A controller then determines the laser power correction factors that are necessary to

maintain a homogeneous heat distribution. In the next layer these correction factors are considered, and the laser power is adjusted accordingly. This process repeats layer by layer at a high optical resolution of approx. 100 µm. Thus the number of iterations needed to get a part right is reduced to 1 along with the possibility to reduce support structures to a minimal level.

Results:

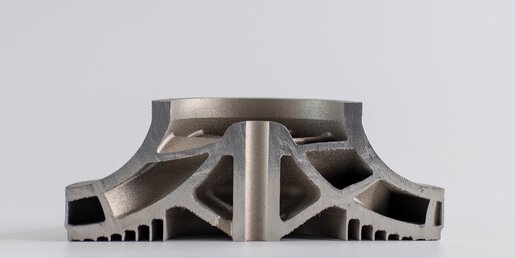

- Drastically reduce the support structures on a bracket

- Produce an aerospace fuel tank with a 0-degree overhang without any support structures

- Enable production of a large impeller

Want to learn more? Get the free Whitepaper here.