The Realities and Benefits of Support-Free Metal 3D Printing

What does support-free mean

In additive manufacturing (AM) support-free building refers to developing ways to produce 3D printed parts entirely independent of any support structures. Supports are commonly used in the process of a build to reinforce and maintain the structure of the part being created. This is necessary for various reasons, depending on the size and shape of the part being constructed.

The supports are placed strategically to prevent deformation from thermal stresses, encourage heat transfer away from the melted material and protect the forming part from the recoater blade, which may cause disruption to the part’s shape if impacts occur. They can also provide additional rigidity to the part during the build process — for instance, attaching it to the build plate to keep it steady.

To build up layers of the additive material in the right shape, some of the powder is used to create supports to hold up protruding elements of the part being printed. The idea of support-free printing would do away with those supports, allowing a part to be constructed entirely free-standing and ready to go as soon as the print is completed.

Advantages and disadvantages of 3D printing with supports

Supports essentially function as small raised build platforms under the part being made. These provide additional structure to the build. In some circumstances, without the right support, a part will fail to fully form. This is most common with overhanging sections of a part or where a part needs a hole that goes all the way through it; either of these scenarios will only progress so far before they’re unable to anchor themselves during the build process. Using supports allows for parts with a narrow base or gaps to be produced. As a general rule, supports tend to be required for any aspect of a build that extends under 45-degrees from the build platform — this means any part that elevates at an acute angle may need supports factored into the build.

While the construction of supports during the AM process are beneficial to the creation of more complex and elaborate parts, it does also have several drawbacks. These are mainly in relation to materials, print times and post-processing.

Draw-back #1 - Print times

Each of the supports needs to be progressively printed with each layer of the build, in the same way that the part itself is created layer by layer. This results in longer print times that reduce efficiency and use more energy, impacting the cost of builds in more ways than one.

Draw-back #2 - Material consumption

As the supports are constructed in the same way as the rest of the part being built, it means that superfluous materials are used to create them. The supports are removed from the final product in post-processing and disposed of as waste material, which affects time and costs.

Draw-back #3 - Post-processing

Most 3D printed parts go through a post-processing stage, which can consist of several stages, depending on what’s required to finish the part and make it suitable for use. This can include machining and a surface treatment to enhance the tolerance of the part and reduce surface roughness, and heat treatment for improved mechanical properties and the removal of thermal stresses incurred during the build process. A final cleaning stage is often required to remove extraneous powder. Building with bigger and more supports requires a longer and more intensive finishing process compared to if the supports could be reduced in number or size. This time-consuming process is not only manually demanding, but it also comes at an additional cost. Specialist labor time and the requisite tools add to the bottom line for product manufacturing.

There are also instances where some supports are inaccessible and therefore cannot be removed. While these may not prevent the part from functioning, they will add weight and potentially impact the overall performance of the part. In the case of precision-engineering, the ability to print without those supports could have resounding benefits for the future use of the part.

The benefits of support-free building

By shifting to support-free 3D printing, the AM process can be improved economically, environmentally and in regard to time. Not needing to construct supports during the build means less of the material in the powder bed will be melted, which has multiple benefits for AM.

Manufacturing Speed Hack #1: Cut down production time

If the lasers in the printer don’t need to continually add layers to the supports as the build progresses it will cut down on the print time. While for each single layer of the build this will have a small time-saving impact, over the course of a complete build, it begins to add up to a significant reduction in the time it takes to complete the production of a part. Applied to manufacturing on a large scale, this empowers companies to cut down on production times by an even more significant amount.

Manufacturing Speed Hack #2: Save post-processing resources

Not having supports in the first place would mean their removal is completely eradicated from the post-process phase, which often has a significant impact on lead times. A large amount of the time spent in post-processing is focused on the removal of supports. Because they are attached to the final product, they need to be removed and the surface treated until it’s matched perfectly with the rest of the part’s surface. To do this requires specialist skills and tools that cost companies money and time. In extreme cases, a one minute processing step during the build can lead to an increased lead time of one day. A support-free build would do away with the need for such intensive post-process adjustments, making it far quicker and cheaper to complete a part. Without needing to remove the attached supports, the printed part will also have better, more consistent surface finish immediately.

Manufacturing Speed Hack #3: Consume less material and lower the environmental impact

With sustainability and responsible manufacturing in mind, it’s clear that not using supports — or even reducing them in size and number — will mean less material is used. This results in a lower level of material waste and reduced energy expenditure, cutting down on both the financial and environmental cost of 3D printing. It also reduces the overall time of both the initial printing process and the post-process procedure to finish the part, allowing for greater efficiency and simplicity.

What’s possible in support-free 3D printing?

The reality is that 100-percent support-free AM currently isn’t possible for every application or geometry. That isn’t to say that it may not be in the future, though — at EOS Additive Minds we’ve recently made some incredible leaps in getting closer to that end goal of support-free printing.

Probably the most sustained limitation of metal AM is that you cannot print below a certain overhang angle without supports. Without supports, the overhang is at risk of warping due to the residual stresses caused by exposure to the focused energy of the lasers during the print. This often restricts users of metal AM systems in their choice of applications.

Thanks to the innovative thinking of industry leaders, the critical 45 degree angle is now being questioned and challenged. Many software and parameter packages have now become available that enable users to print overhangs and bridges at much lower angles, without compromising the effectiveness of the 3D printing process and quality of the metal parts produced.

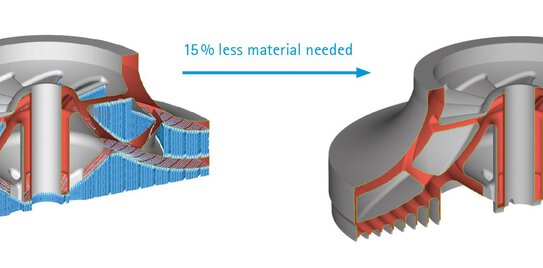

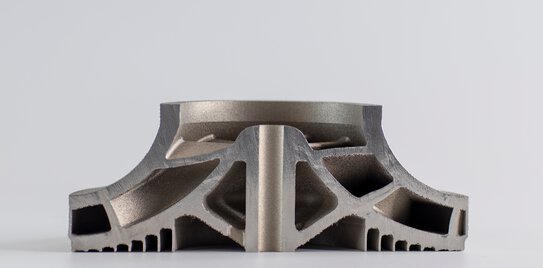

Take a look at this case study on shrouded impellers, where a support-free build was achieved despite pushing the limits of overhang angles to an impressive 10-degrees.

This particular project also saw the complete elimination of internal supports, which makes the post-processing procedure much less complicated — awkwardly placed supports inside a part can be some of the most challenging to remove, even if they’re not the largest. Through these reductions in the size and number of supports, the overall cost of production for the impellers was reduced by 35 percent.

The process development team have taken the findings from bespoke, specialist projects like this and applied them to the standard processes that are available for “plug and play” 3D printing software. This means that now, even without an expert consultant, you can reduce angle limits to 20-degrees as standard.

How EOS supports you in support-free printing

Our specialist software, EOSPRINT 2, is designed to ensure it offers the most versatile platform to manage your 3D printing needs. For those looking to get started in the world of additive manufacturing, it comes preloaded with a series of “plug and play” solutions. These give you everything you could need to build products simply, without having to configure or adjust parameters. The advanced programming in the software handles much of the work for you, so you can print with ease.

For those with experience in 3D printing, EOSPRINT also allows for more experimentation and calibration. Instead of using the preset solutions you can manually alter settings yourself. This is perfect for anyone wishing to enhance their additive manufacturing while secure in the knowledge that the software you’re using is of the highest quality.

To support you in your development of 3D metal printing and help you get the most out of the capabilities of our software, we offer an eLearning course. This 3D printing module will provide a comprehensive overview of support-free additive manufacturing for metal, providing you with specialist knowledge to reduce costs, save time and drive innovation across the process chain.

Finally, if you have a specific project that you want to see come to fruition, our Additive Minds team is here to help. For any bespoke project that requires a greater level of consideration and understanding than our software packages can provide, this is the best place for you to be.

No matter what level of experience you may have - We assist you in your pursuit of support-free 3D metal printing