An Outstanding Technology for SLS 3D Printing

Selective laser sintering (SLS) 3D printing is a professional additive manufacturing technology trusted by a broad variety of manufacturers for its ability to create functional and robust plastic parts.

Discover what makes SLS technology so powerful and find out more about the SLS 3D printing process and our systems. EOS has captured more than 30 years of experience in industrial 3D printing and offers a wide range of polymer 3D printers and materials.

How Does Selective Laser Sintering (SLS) 3D Printing Work?

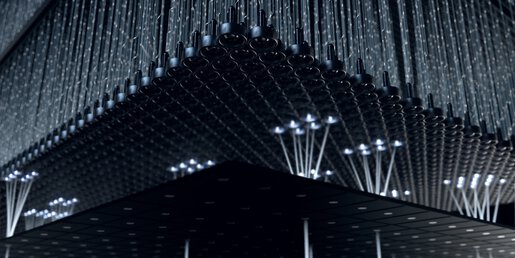

The EOS SLS 3D printer uses a laser to melt polymer powder and fuse it into a solid 3D printed part. SLS is part of the Laser Powder Bed Fusion (LPBF), one of the most advanced and reliable technologies in 3D printing.

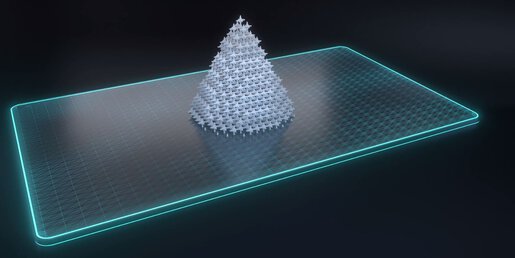

Using a CAD design model, the laser melts the plastic material precisely at the predefined points in the powder bed. The technique requires no support structures, as the unfused powder supports the part during printing. After completion of the melting process, a new layer of powder is applied. This process repeats layer by layer until the part is completed.

SLS is a new high end method that has been primarily used for rapid prototyping and small batch production of components. Within the process of commercialization of selective laser sintering, the production tasks are being expanded enabling new design options for a wide range of products.

What Are the Benefits of EOS Selective Laser Sintering?

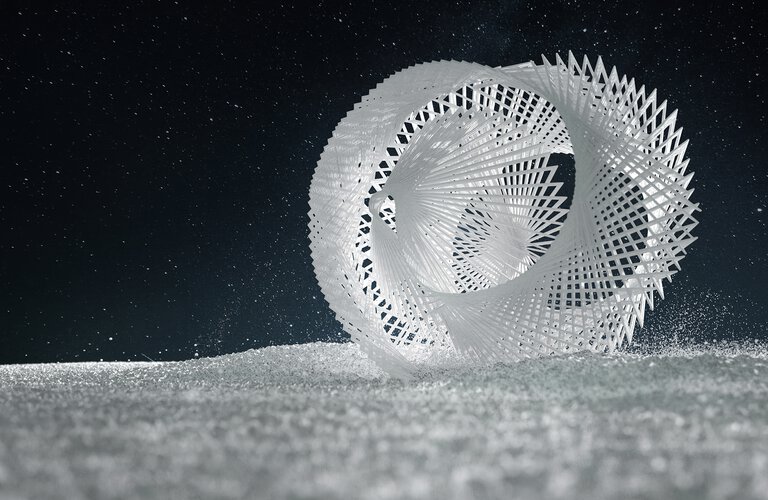

Selective Laser Sintering is an ideal and outstanding method and is used for complex parts and very popular in the field of plastic 3D printing due to its various advantages. Unlike some other 3D printing technologies such as stereolithography (SLA) and fused deposition modeling (FDM), the SLS 3D printing process does not require support structures. This enables the production of very complex, almost impossible 3D printed patterns. Only powder and power are needed to produce parts, no binders or additives.

Spotlight on Quality: Experience in 3D Printing since 1989

SLS systems for every 3D printing need

Are you looking for an Selective Laser Sintering 3D printer for your production? EOS offers a wide range of SLS 3D printers tailored to your individual needs - from compact systems to modular and digitally networked 3D printing platforms for serial production on an industrial scale.

SLS 3D Materials for Plastics 3D Printer

The right material is critical for a good result in selective laser sintering. At EOS, we have exceptional material expertise and a comprehensive portfolio of advanced plastic and polymer 3D printing materials for the 3D printing process.

The most common material for selective laser sintering is nylon, also known as polyamide. Parts made from nylon are robust, long-term stable, chemically resistant and extremely versatile. At EOS, we offer two versions of nylon: PA 11 (Polyamide 11) and PA 12 (Polyamide 12).

In addition to these standard plastics, EOS is also constantly developing its range of high-tech materials for special customer requirements, such as the flexible TPU or high-temperature PAEK (polyaryletherketone).

Get your personalized offer now