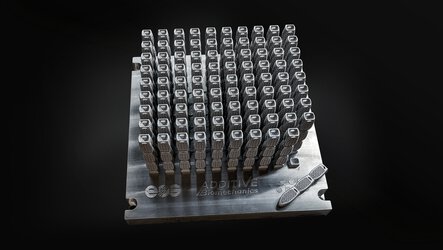

When 3D printing with metals, parts are subject to stresses during production and therefore typically require support structures to prevent degradation during the build. These supports are created directly within the design data and manufactured additively in conjunction with the 3D printed object. This step of the 3D print is required to protect the metal parts against thermal stress induced deformation during the build and to effectively conduct away the heat from the molten pool in overhang areas. Once the part is finished, the support structure is removed either manually or automatically.

To 3D print parts without any supports, or at least minimize the number of supports used, improves post-processing but can also reduce the print time, if applied effectively, and cut down on material consumption, saving on costs and reducing the environmental impact of builds.

Our experts at Additive Minds have tackled the question of how such a printing process might work and what challenges it would entail.

Using supports in 3D printing: How it’s been until now

Designing a 3D print with supports has always been the standard method in additive manufacturing (AM). The number, size and placement of supports is determined by multiple factors.

- Residual Stresses during the print process can result in deformations to the 3D model. Supports can be added to physically prevent this deformation.

- Disruption From The Recoater impacting the part mid-build can vibrate the part or cause damage that renders the job unsuccessful. Supports are used to protect the part from any impacts from the recoater.

- Heat Transfer via the supports allows the part to cool and form quicker and more successfully during the build process.

Supports are used for various reasons to ensure a build will complete and the part is produced successfully, including:

- Part Orientation dictates how much of the part requires support. Generally, more supports are needed to compensate for the above factors if the part is oriented so a greater amount of the surface area is not on the build plate.

- Overhangs of 45 degrees or less are commonly considered to need a support structure.

- Channels And Holes can misform without supports, depending on their size and if they are ineffectively oriented.

With Smart Fusion to a More Efficient Manufacturing Process

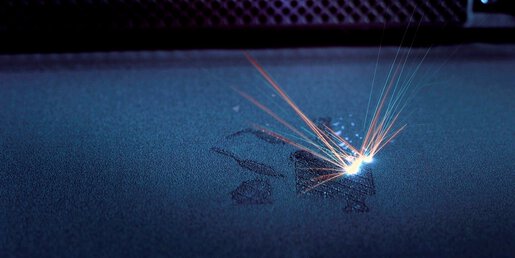

Support-Free technology enables production that takes into account both cost and time savings. To make this process as efficient as possible, EOS offers the automated process control solution, "Smart Fusion", a software solution that can reduce or eliminate the need for support structures.

Eliminate support by adjusting laser power in real-time using the tomography camera (OT) and advanced algorithms.

Reduced post-processing the reduction or elimination of support structures, not only saves material but also reduces the amount of post-processing needed for built parts.

Accelerated production time is also a positive side effect of eliminating support structures. This makes the manufacturing process more efficient, particularly for prototyping and the production of spare parts.

A wide range of applications are achievable with the assistance of Smart Fusion technology, ranging from robust components for the automotive industry to customized implants for medical applications. Push the boundaries of your additive manufacturing capabilities with the help of EOS software technology.

3D Printing Without A Support Structure

With the right expertise and creative problem-solving skills, teams at EOS have succeeded in developing new ways to design builds that don't conform to the previously held preconceptions of what's possible, producing excellent results.

Take a look at our blog about support-free 3D printing which gives insights into the reality and benefits.

Our experts have worked on many projects where using no or minimal supports can lead to optimized builds, with reduced costs and timeframes. The challenge of overcoming the perceived restrictions of 3D printing without support has led to creative solutions that can advance 3D with metals into the future.

Discover more with our support-free 3D printing whitepapers

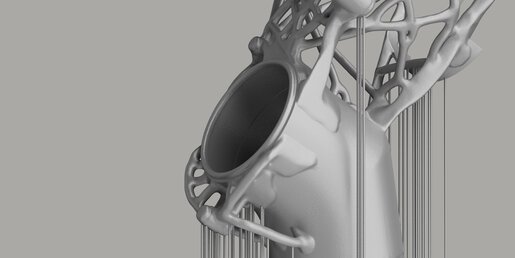

To learn more about the intricacies of 3D printing metals support-free, take a look at our whitepaper, written by Additive Minds team manager, Davy Orye. This paper details the process and rationale behind developing a way to produce shrouded impellers completely support-free.

Download our Smart Fusion whitepaper now to learn more about how the software may benefit your next AM build. Learn how Smart Fusion has been used in real-world applications and what design guidelines should be considered in our whitepaper.

The Applications For Support-Free Print Methods

Printing parts support-free has many incredible benefits. At EOS, we’ve found innovative ways to take support-free methods and apply them to various build projects, with resounding success in build time, cost and material reduction. Here are some of our highlights.

Probably the most commonly sustained limitation of metal AM is that you cannot print below a certain overhang angle without supports. Without supports, the overhang is at risk of warping due to the residual stresses caused by exposure to the focused energy of the lasers during the print. This often restricts users of metal AM systems in their choice of applications.

Thanks to the innovative thinking of industry leaders, the critical 45 degree angle is now being questioned and challenged. Many software and parameter packages have now become available that enable users to print overhangs and bridges at much lower angles, without compromising the effectiveness of the 3D printing process and quality of the metal parts produced.

Take a look at this case study on shrouded impellers, where a support-free build was achieved despite pushing the limits of overhang angles to an impressive 10-degrees.