Additive Manufacturing with Metals Metal 3D Printing Processes and Part Quality

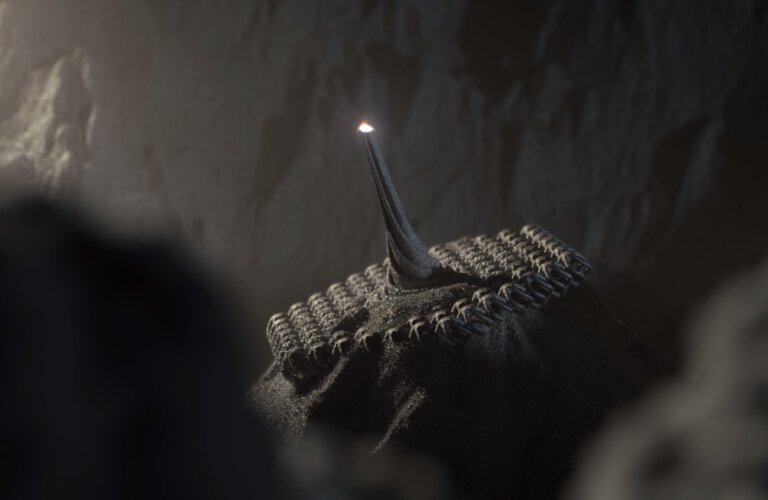

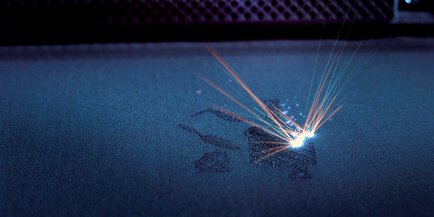

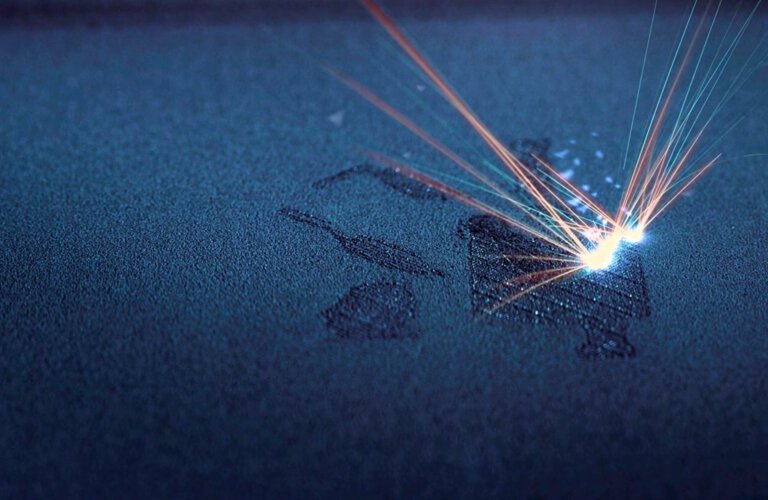

Metal-based additive manufacturing encompasses a wide range of technologies such as powder bed fusion (PBF), metal binder jetting and laser cladding. DMLS®, as used by EOS metal 3D printers, follows the principle of - in German - "Direkt Metall Laser Schmelzen" (DMLS, Englisch translation Direct Metal Laser Melting). It is the proven PBF technology of choice for EOS for almost three decades, and is now the standard in metal 3D printing. The DMLS method is primarily used for manufacturing in demanding industries such as aerospace, automotive, medical, tool and turbomachinery. These industries require uniform part quality with properties like those achieved by conventional casting or forging processes.

We are the leading global provider for industrial metal 3D printing. Thanks to our DMLS technology and our broad portfolio, we empower our customers to achieve reliable and repeatable part quality.

The EOS Metal Additive Manufacturing Machines and Materials for Your Metal 3D Printing Needs

EOS metal 3D printers are available in various formats, from entry-level models to multi-laser machines for additive series production at industrial scales. We also offer validated processes unique in industrial metal 3D printing, as well as the most comprehensive portfolio of metal materials, including aluminum, cobalt chrome, nickel alloys, titanium, refractive metals, stainless steel and tool steels.