Benefits of Additive Manufacturing For Tooling Applications

Costs are lowered through a 17 % cut in cycle times for the plastic injection moldings

Production plant maintenance extended from every two weeks to every five or six

Uniform cooling prevents deformation of the plastic end product

Metal 3D Printing for Conformal Cooling Innomia optimizes production process for injection molded plastic parts

Innomia uses EOS 3D printers for optimizing the production process for injection molded plastic parts. This involved a revision of the cooling process. The case concerns the manufacture of the armrest situated between the front seats.

Why Conformal Cooling?

The heat energy of the liquid base material needs to be dissipated throughout the manufacturing tool to enable the plastic to solidify. The cooling process dictates, amongst other things, the quality of the component. This is because irregular heat dissipation can lead to deformations.

As a logical consequence, the designers from Innomia began to develop a new tool insert cooling system. The optimized removal of heat generated in the production process was right at the top of the list of priorities.

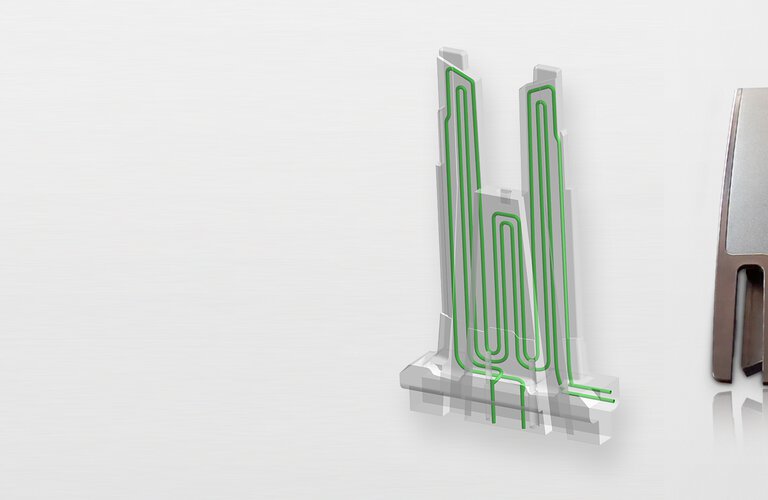

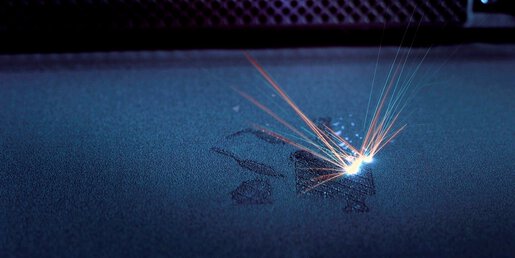

The team decided to go with integrated precision cooling channels, conformal cooling, a tried and tested application under DMLS technology, and one of the solutions that only Additive Manufacturing processes can provide. The EOS metal 3D printer, a system proven over many years, was deployed for Innomia.

The precision cooling and the production using Additive Manufacturing technology has had the desired results. The temperature distribution and associated heat dissipation are now substantially more homogenized. Since the heat is distributed and leaves both the tool and the component quicker, a water temperature of 60 °C is sufficient for cooling – reducing the energy needed. The insert surface itself does not heat up beyond 90 °C, a fact that further allowed the engineers to resolve the humidity problems in the surrounding area.

The issue of cooling was something that we've been trying to deal with for a long time. We knew how an improved product would have to look, but manufacturing it just wasn't possible. Additive manufacturing allowed us to make the breakthrough. We were able to plan the cooling channels just as we wanted them and then manufacture the mold core correspondingly. The laser fuses the metallic powder layer by layer, so that in effect any shape is possible. The result has convinced us at every level. Maintenance, quality of the end product, costs, heat dissipation – it's been the perfect project.

The Results at a Glance

Production plant maintenance extended from every 2 weeks to every 5 or 6

The automobile industry in Europe is subject to stiff competition. This fact naturally has an effect on suppliers such as Magna. That’s why it’s very important for us to be able to produce to the highest quality standards at the lowest price. With the optimization of our production plant via the improved cooling of our tools, we have created a textbook example of how technology can help increase efficiency. We reduced the maintenance costs for our production plant, optimized the quality of our components and increased the number of production cycles. This enabled us to uphold the promise of quality we made to our client and, at the same time, meet our own high demands regarding cost-effectiveness.