Do We 3D Print or Additively Manufacture?

History of 3D Printing. Names for New Technologies

Currently there are two dominant terms used for our industry and class of technologies: the official standard Additive Manufacturing and the de facto standard 3D Printing. Let’s take a look at where these terms came from and what they mean.

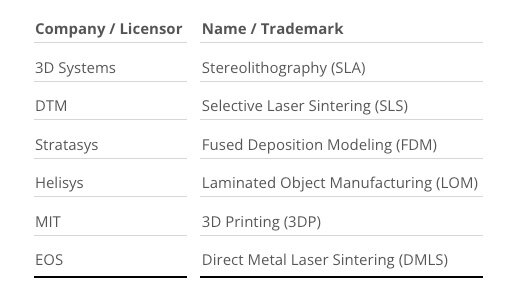

There is a need for names for individual technologies, and for what they are used for. The latter is often synonymously used for the respective industry, i.e. for the suppliers and users of such technology in general. Our industry started with several different technologies which were commercially introduced within a few years in the late 1980s and early 1990s. Each of these were named by the commercializing company, or in some cases the licensor of the technology. The following table summarizes some of the main early technologies:

It is interesting to note that 30 years later, most of these names and abbreviations are still being used in a similar way, while one of them has morphed into a more generic usage. 3D Printing originated as a technology developed by Emanuel Sachs’ team at Massachusetts Institute of Technology and described in their 1989 patent application as:

3D Systems initially promoted their technology for “Rapid Prototyping”, and as this was the first commercialization, the term soon became widely used. For example, the first main industry journal was called “Rapid Prototyping Report”, and the early conferences organized by the University of Dayton were called “International Conference on Rapid Prototyping”. It was quickly realized that the technology was applicable to much more than just prototyping, so the terms rapid tooling and rapid manufacturing were often added. For many years the major annual conference and trade show organized by SME was known simply as “RAPID”. But right from the start, alternative terms were also used.

The University of Texas used the term Solid Freeform Fabrication (SFF) for its publications and conferences, and the author Marshall Burns titled his 1993 book “Automated Fabrication” and tried to establish the terms fabricator for the machines and “fabber” for the users. The company name DTM was derived from “Desktop Manufacturing”, while other terms included solid imaging, layer manufacturing and additive manufacturing.

Additive Manufacturing, 3D Printing: Need for standardization

As the industry developed, there was an increasing need for standardization. On the one hand to minimize misunderstandings, as some terms (such as 3D printing) were being used to means different things. But also, to establish generic terms for the technologies whose popular names were in many cases trademark-protected. The first standardization activities were coordinated by VDI in Germany, and it is no coincidence that their first publication relating to these technologies included terminology: the German/English edition of VDI3404 from 2009 (based on a German-only draft from 2007) was called “Additive fabrication – Rapid technologies (rapid prototyping)”. It stated:

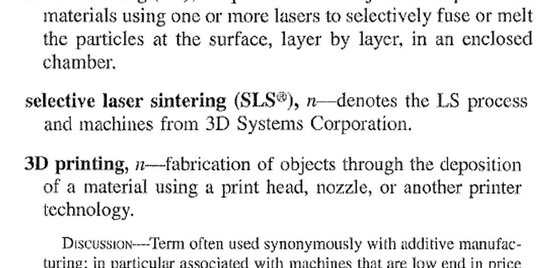

The standardization efforts quickly became more international, and soon established “additive manufacturing (AM)” as the official industry name. For example, ASTM International established a Committee F42 Additive Manufacturing Technologies, which published the ASTM F2792 “Standard Terminology for Additive Manufacturing Technologies”. This standard included both proprietary and generic terms. Regarding 3D printing, it confirmed the “proper” usage as a technology name, whilst acknowledging the alternative popular usage.

Through a cooperation between ASTM F42 and the ISO committee TC261 Additive manufacturing, ASTM F2792 was subsequently replaced by the international standard ISO/ASTM 52900 “Additive manufacturing — General principles — Terminology”. This standard uses exclusively generic (non-proprietary) terms, so that for example laser-sintering falls within “powder bed fusion” and stereolithography belongs to “vat photopolymerization”. But it maintained the same definition of 3D printing. EOS employees actively participated in the creation of these standards, and continue to work in the relevant ASTM and ISO committees to maintain and expand the AM standards.

Additive Manufacturing: A maturing industry

In parallel to the standardization activities, the technology and industry had been making huge progress in at least two different directions. On the one hand, there was rapid growth of companies offering low-cost machines aimed at domestic and hobby users. Although most of these were based on material extrusion (fused deposition modelling) technology using filament feedstock, the machines were frequently referred to as 3D printers. This trend was accompanied by significant hype in the press and from business consultants, many of whom predicted that within a few years millions of households would own 3D printers and 3D print spare parts and household objects.

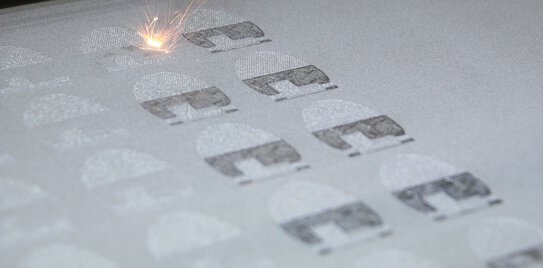

On the other hand, industrial Additive Manufacturing technologies like laser-sintering had achieved such levels of capability and maturity that they were being used to produce even highly critical and regulated products such as medical implants and aerospace flight components. Understandably, the manufacturers and users of such products wanted to avoid being “associated with machines that are low-end in price and/or capability”, i.e. 3D printing (as described by ASTM/ISO). This situation presented a dilemma for companies like EOS, whose target customers were mainly in the high-quality industrial area, but risked lack of exposure if they distanced themselves too much from 3D printing.

Additive Manufacturing, 3D Printing: Development of the status quo

The development of terminology as described above can be observed nicely by looking at State of the Industry Reports which have been published annually by Wohlers Associates since the 1990s. As independent observation of both the providers and users of the technology, these reports reflect very well the general terminology usage in each year. The following table summarizes how the terms used in the title or introduction of the reports has changed over the years:

Terms used in the annual Wohlers Associates “State of the Industry” Reports

1996: Rapid Prototyping

1998: Rapid Prototyping & Tooling

2003: Rapid Prototyping, Tooling & Manufacturing

2006: Rapid Prototyping and Manufacturing

2007: Additive fabrication, also known by other names such as rapid prototyping

2009: Additive Manufacturing (AM)

2021: 3D Printing and Additive Manufacturing

The status quo is as follows:

- The standards development organizations (ASTM/ISO etc.) generally maintain the terminology, which was developed mainly by industry and academia, i.e. Additive Manufacturing, whilst referencing 3D printing as a commonly used synonym.

- Industry organizations, at least in the B2B area, generally also use AM, for example the Additive Manufacturing Users Group AMUG, the Additive Manufacturer Green Trade Association AMGTA, the Association for Metal Additive Manufacturing AMAM etc.

- Governmental organizations such as America Makes and the EU tend to use both terms, e.g. “America Makes is the nation’s leading and collaborative partner in additive manufacturing (AM) and 3D printing (3DP) technology research … we innovate and accelerate AM/3DP”.

- Journalists, authors, consultants etc. often use the term 3D printing, also when referring to industrial applications, but sometimes also AM. For example, the Wohlers Associates website refers to “additive manufacturing and 3D printing - terms that are used interchangeably”.

- Suppliers and users of AM technology, including EOS and many of our customers, tend to use both terms synonymously and intentionally include both in their public communication, in order to address all kinds of readers.

It remains to be seen how the terminology and its usage will develop in future, but we can be sure that the technology and its application will continue to mature and expand.

Author: Dr. Mike Shellabear