Cost-Efficient 3D Printing-Based Manufacturing for Aviation Reduce Fuel Consumption and Material Costs, Lower CO2 Emissions

As air traffic is steadily growing, the total volume is expected to roughly double over the next fifteen years. Even today, the industry is already under heavy load, as building and maintaining freight and passenger aircraft is a growing challenge. The CO2 emissions from operating flights also need to be reduced. And additive manufacturing paves the way for solutions.

In the aircraft construction sector, 3D printing makes faster production processes possible. Manufacturing can be performed precisely when needed. Another advantage: demand-driven additive manufacturing does not generate any of the excess or surplus that often occurs with series production. The process also allows lighter parts to be manufactured, which noticeably reduces the fuel consumption of the machines – the lower the weight, the less fuel is burned.

Constructing engines and turbines means mastering challenges such as optimizing volume, performance and environmental friendliness. In these areas, 3D printing can make a significant contribution. It allows engines with sophisticated geometries, defined aerodynamic and fluid dynamic properties to be produced, as well as lightweight structures whose individual parts weigh up to 60 % less. Processing superalloys is also more cost-effective with 3D printing, since the material usage rate is lower. The results: significantly reduced environmental pollution over the lifetime of the aircraft. Parts made from a single piece are also more resilient and less susceptible to damage.

EOS Technology for Aviation What Our Customers Have to Say

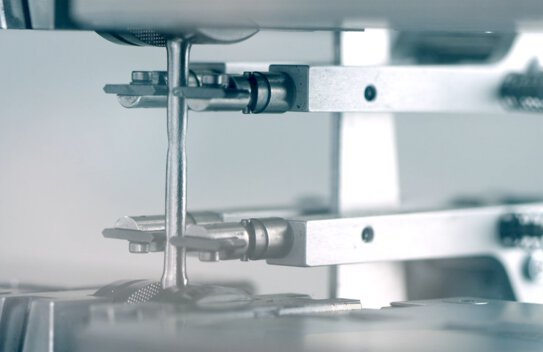

Airbus is a global leader in the aerospace industry and related services. 3D printing technology by EOS helps Airbus to build a more cost- and resource-efficient aircraft. Additively manufacturing a locking shaft for aircraft doors achieved remarkable results:

- 45 % weight reduction of the additively manufactured part, while keeping the same robustness

- 25 % savings in production costs by reducing material usage and assembly times

- Number of parts reduced from 10 to 1

- Weight reduction of more than 4 kg across 16 door shafts installed in an A350 aircraft

The component was made from titanium on the EOS system EOS M 400-4.

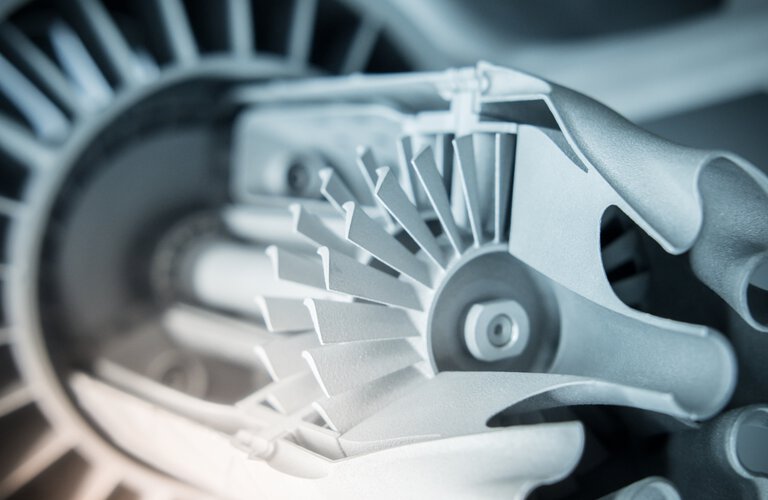

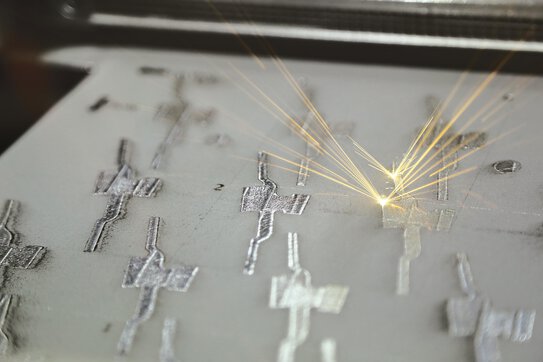

MTU Series Production of Parts for an Airbus Engine With EOS Systems

MTU Aero Engines, Germany’s leading engine manufacturer, has optimized its EOS machines to manufacture safe and cost-efficient parts in series. Using additive manufacturing, MTU builds borescope bosses for the geared turbofans of the new generation of PurePower® PW1100G-JM engines by Airbus A320neo. The low-pressure turbine in the A320neo turbofan is the first turbine ever to be equipped with additively manufactured borescope bosses by default. The cost benefits of EOS technology were one of the decisive factors for both production and development.

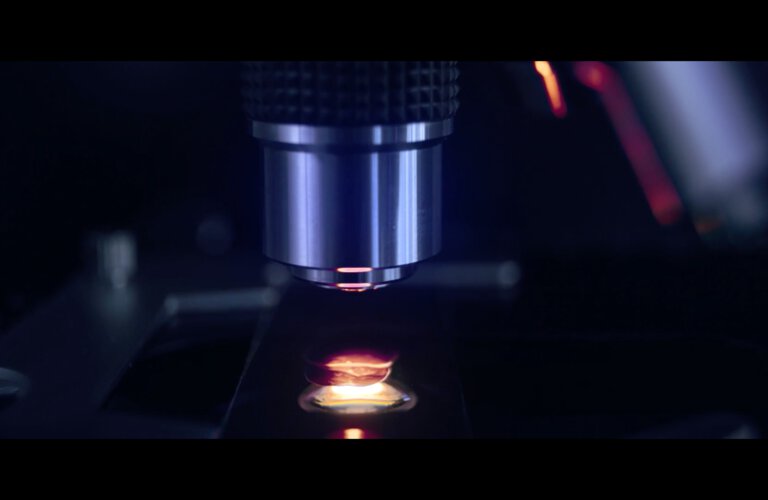

Quality Assurance for Aviation Efficient Process Monitoring With EOS Exposure OT

The high safety requirements for approval are a major challenge in the aviation sector. Every part destined to fly has to be monitored continuously from raw material to end product, and there cannot be any defects. In collaboration with EOS, MTU Aero Engines developed an optical tomography technique for the build process into a serial product called EOSTATE Exposure OT. The parameterizable software allows detailed conclusions to be drawn about the quality of parts at every layer. In this way, optical tomography enables reproducibility to be verified, improves comparability between parts, build jobs and printing systems and creates the right conditions for cost-efficient quality assurance in series production applications.

Still have questions? We’re happy to advise you.

Reduce cost drivers – a key factor to manufacture structural parts for the aviation sector more efficiently. Digitalized manufacturing processes offer wide-ranging opportunities. Thanks to additive manufacturing, multiple parts can be combined into a single component, eliminating production steps such as assembly. The process of storing spare parts, which currently ties up a lot of capital, is also becoming obsolete. Production only ever occurs when a part is needed, without requiring any preliminary processes. Additionally, additively manufactured structural parts are comparatively lighter, which helps to balance the CO2 footprint of aircraft.

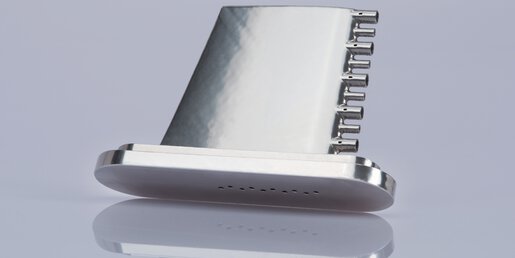

Liebherr Parts for the Primary Flight Control of the Airbus A380

Liebherr Aerospace is a leading supplier of systems for the aviation industry. With more than fifty years of experience, the company develops, manufactures and maintains a variety of aircraft instruments, including flight control and actuation systems, landing gears, air management systems and gearboxes.

Using their metal 3D printer, the EOS M 400-4, Liebherr produced an innovative high-pressure hydraulic block for the Airbus A380. The new additively manufactured valve block achieves the same performance as the conventionally made part but is much lighter and contains fewer individual components. The part is made from a titanium alloy and satisfies all of the certification requirements needed for flight operations.

Additive manufacturing with polymer technology is also becoming increasingly important for cabin interiors. There are several reasons: in this type of environment, high customization and flexible tool-free production are crucial. Materials used in the cabin also have to satisfy very strict requirements, e.g. in terms of flammability. The technology needs to be capable of processing these materials, especially when complex designs such as twisted strands are required. Finally, a consistent build process is necessary, with minimally complex post-processing, as well as a digital spare parts strategy and digital spare parts, with virtual inventories. Polymer technology for industrial 3D printing meets all of these criteria.

Etihad Engineering The Aircraft Cabin of the Future

Etihad Engineering is the largest service provider for aircraft maintenance, repair and operations (MRO) in the Middle East. As a subsidiary of the Etihad Aviation Group, the company offers around-the-clock maintenance services, including design, composite material repairs, cabin refitting and part-related services, in its modern facilities at Abu Dhabi International Airport.

The EOS P 396 system allows parts to be manufactured from polymer materials such as PA 2241 FR and can therefore be used to manufacture cabin parts that are replaced during the aircraft inspection process known as C-checks. Defects can also be remedied quickly by manufacturing any needed parts while performing maintenance during regular aircraft downtime (line maintenance).

Etihad and EOS are known for high-quality solutions and technological innovations and share the same mindset: “Together, we want to take the design and production of parts for aircraft interiors to the next level,” says Markus Glasser, Senior Vice President for the EMEA Region at EOS. “Additively manufactured cabin interior parts offer significant added value thanks to the simplified repairs, lightweight design, shorter lead times and flexible customization options. This tackles some of the key challenges of the aerospace industry.”

More Success Stories of Our Customers 3D Printing for Aviation in Practice

Certification and Scaling of Your 3D Printing Applications Additive Minds Consulting

Want to certify and scale your production? We can give you the know-how you need.

Our Additive Minds Consulting team makes it easier for you to implement robust processes that guarantee all-round stable industrial 3D printing production. In this way, you can generate detailed documentation to demonstrate that your production facilities and methods will operate smoothly, even in series production. We support you with certification for the standards you need.