With Additive Manufacturing, Design-Driven Production Becomes a Reality

Industrial 3D printing means that the manufacturing process no longer determines the complexity of a component, but rather the product’s desired functionality and design. Complex geometries, such as three-dimensional structures with undercuts or cavities, are typically impossible to manufacture with conventional technologies like milling, turning or casting, or are only possible at disproportionately high costs.

Now, any shape that can be constructed in a 3D CAD program can be produced with additive manufacturing technology. There are almost no restrictions – even when manufacturing hollow structures. This works because the material is only added where it needs to go. Additive manufacturing gives developers maximum geometric design freedom, and complexity only plays a minor role in the production costs. The costs can often even be significantly reduced due to lower material consumption.

EOS technology was a logical choice for us because we manufacture small series productions with complex shapes. We acquired the high-temperature system EOS P 800 at an early stage and were able to rapidly make progress in the development cycle of OsteoFab™ technology. EOS accompanied us throughout the entire process.

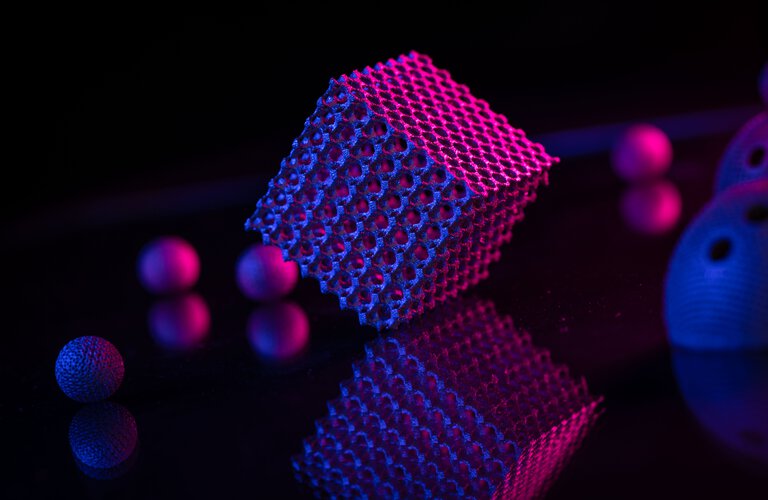

3D Printing of a Hip Cup

Multiple structures in the same part

Thanks to 3D printing, the hip cup implant was significantly optimized. The artificial hip cup consists of solid sections that provide stability and porous elements on the surface. The differently sized pores help to anchor the implant firmly: Large pores are helpful for pressure transmission - smaller pores support the initial fixation. In this way, the complex surface structure simplifies osseointegration, or the growth between the living bone tissue and the surface of the implant.

Flexible structural adjustment possible

The full implant is manufactured in a single production step by the 3D printer and would be extremely difficult to make with conventional manufacturing methods. At the same time, the high flexibility of additive manufacturing enables the structure, surface roughness and pore size to be determined individually for each patient. Together with the Additive Minds Team at EOS and the established 3D metal printing system EOS M 290, Permedica succeeded in realizing a completely new product.

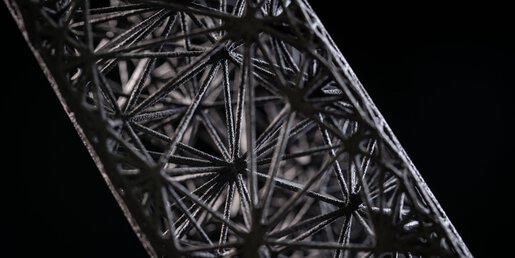

Bionic Structures Nature as a Model for Additive Manufacturing

Evolutionary processes have created biological structures in great abundance and diversity: today, we know of more than 1 million species of animals and around 500,000 species of plants. These systems often have shapes and structures that are optimally adapted to their environment and are created with minimal use of materials and energy. The interdisciplinary research field of bionics aims to exploit this massive potential by adapting natural blueprints to technical applications.

This is where conventional manufacturing processes encounter their limits. By contrast, additive manufacturing achieves maximum design freedom. With our technology, you have the opportunity to build, discard, re-engineer and continuously optimize your prototypes during development. The tool-free production saves time and money - while offering enormous opportunities. As a result, there have been disruptive innovations in medicine, ergonomics and aviation, for example, especially in connection with aerodynamics.

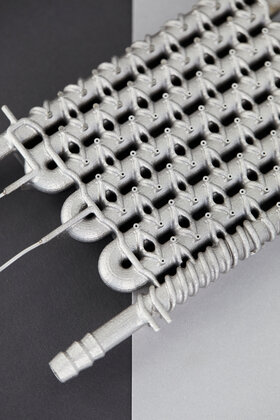

The additively manufactured Festo gripper DHDG is a bionic gripping device that can grip objects gently and flexibly but powerfully, and set them down safely. Its shape and function were inspired by nature. With the FORMIGA P 100 by EOS, the automation specialists Festo were able to produce the parts they needed quickly and cost-efficiently in small series production.

The results are impressive.

Thanks to the superior design freedom, the production can be flexibly guided by the design. By integration functionality into the part during production, Festo succeeded in significantly reducing the number of individual parts and the assembly cost. The resulting gripper is lightweight and durable. And even the price is right: Festo saved time and money with tool-free production.

Implementing 3D Printing Properly Using and Implementing Design Freedom

Thinking in new ways is worth it: you can’t drill around corners, but you can easily print holes. The geometric freedom of design granted by industrial 3D printing opens new possibilities for designers. This requires know-how and a new approach to design.

Are you looking for the right 3D printing solution? Get in touch today.

Advantages of Additive Manufacturing Generate Added Value With Industrial 3D Printing

There are many upsides to 3D printing. EOS technology allows highly complex parts featuring functional integration and maximum product customization to be developed and manufactured quickly.