Production On Demand With 3D Printing

Manufacturers face pressure from various requirements and market demands. In some industries, such as automotive, consumer goods and medical technology, one of these demands is the customers’ need for custom products. At the same time, these products need to be manufactured profitably (keyword: mass customization). Also, suppliers in the automotive and mobility industries, in particular, must guarantee spare parts will be available for 10 years or longer. Producing these spare parts in advance is associated with high material, production and storage costs.

enables production tailored to each batch with almost no limitations when it comes to product customization.

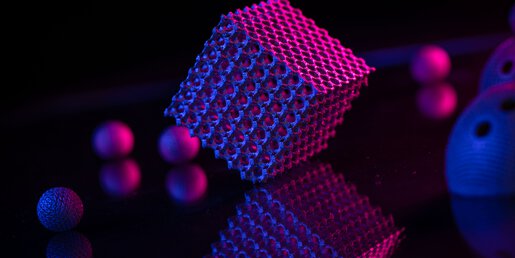

Individual Designs

Perfectly Tailored to Customer Requirements

The Customer Service & Parts (CSP) department at Daimler Buses was faced with the challenge of reducing storage and logistics costs and improving their long delivery times. This was due to an increasingly broad portfolio and its promise to supply spare parts for more than 15 years after the end of series production. Currently, the company is managing over 300,000 active spare parts, many of which are kept in stock – and this number is increasing. Due to minimum purchase quantities, overproduction is a frequent issue. The use of 3D printing technology improved the process substantially:

- 2,500 parts suitable for additive manufacturing were identified

- Redesign and manufacturing on demand (3D printing on demand) of 35 metal and polymer spare parts

- Reduction of storage inventory and the associated costs

- Tool costs reduced to zero

- Reduction of overproduction to zero thanks to 3D printing of spare parts

On-Demand Production in Practice Individual Patient Care With Additive Manufacturing

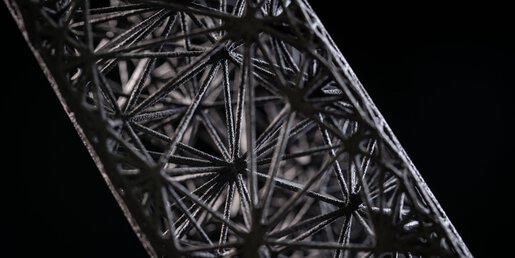

When it comes to supporting orthoses and prostheses, orthopedic technicians usually rely on custom adaptations: Shapes, functions and material strengths are tailored to each patient individually. With complex structures, traditional processes often reach their limits. Production is also time-intensive and expensive, undermining the desire for rapid availability.

In the digital workshop at Mercuris, orthopedic technicians create CE-compliant and individually tailored prostheses and orthoses, which are then manufactured at local 3D printing centers. The shape, function and design of these medical products are optimally tailored to the person who will wear them. Biocompatible plastics can withstand the constant load. The customization and strength of the product help ensure customer satisfaction and growing acceptance of 3D-printed medical solutions.

Not only do tailor-made prosthetic feet enable natural walking behavior, but the additive manufacturing process significantly reduces the lead time, achieves maximum comfort and allows for a customized design.

Are you looking for the right 3D printing solution? Get in touch today.

Advantages of Additive Manufacturing Generate Added Value With Industrial 3D Printing

There are many upsides to 3D printing. EOS technology also allows highly complex parts featuring functional integration and extremely high product customization to be developed and manufactured quickly.