Save Material and Costs With Strong, Leightweight 3D Printed Structures

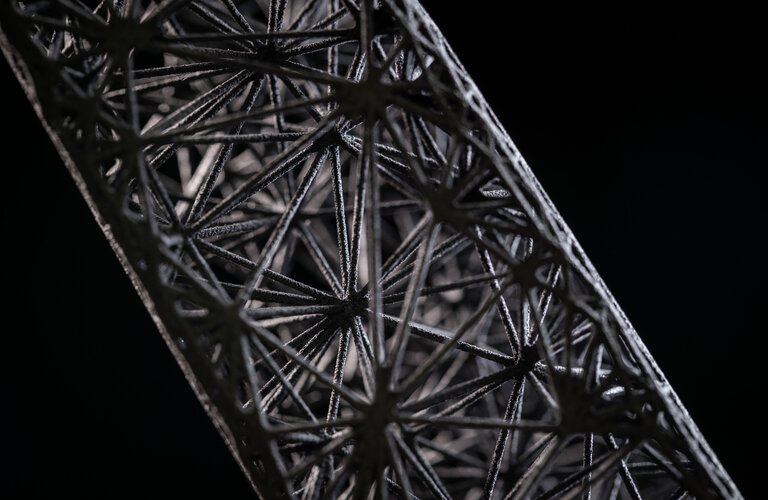

Products should only consume the resources that are necessary for them to function properly. Given that raw material consumption – and therefore resource prices – is growing worldwide, reducing material consumption is increasingly important for product development and production. EOS 3D printing technology makes it possible to design and manufacture high-strength lightweight structures where conventional production processes fail.

For most components, extra material with conventional production can be removed at the design stage. During production, material is only applied where it is functionally necessary.

This results in lightweight, high-strength parts, many of which are used in the aerospace industry. Every gram saved can mean a considerable amount of money saved over the full lifecycle of the part while also helping to protect the environment.

The design freedom of the additive manufacturing process helped us enormously. It allowed us to adapt the design to our requirements and achieve optimal compatibility with our self-developed battery management system – in the shortest possible time, at low cost and with a fully lightweight design.

Lightweight Parts Made With EOS 3D Printers

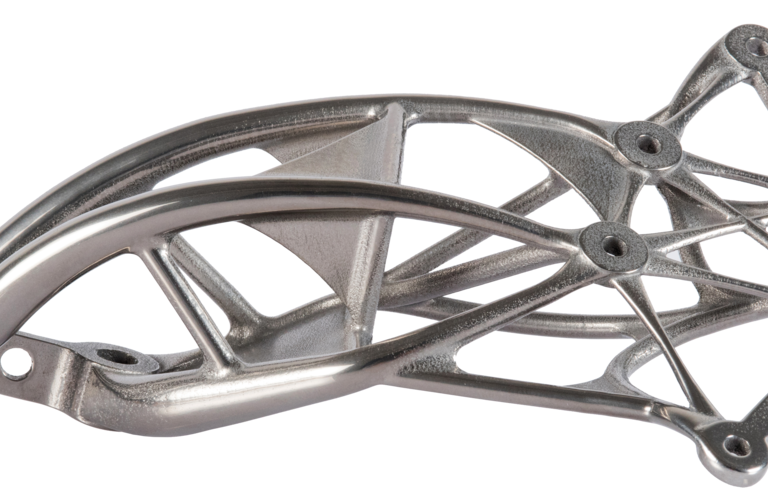

Additive Manufacturing for Space 3D Printed Antenna Mount by RUAG for Satellites

According to data from the German Aerospace Center (DLR) in 2016, mission costs of space travel are over €20,000 per kilogram of transported payload. Every gram saved reduces the total cost of a rocket launch. The engineers must fine-tune every single part to ensure an optimally designed, light and stable antenna mount.

At the Swiss company RUAG, they were successful:

- Minimum stiffness requirements exceeded by more than 30 %

- Weight reduced by 40 % thanks to a new design

- Space industry requirements passed by tests

Airbus is a global leader in the aerospace industry and related services. 3D printing technologies from EOS helps the company to build a more cost- and resource-efficient aircraft. Additively manufacturing a locking shaft for aircraft doors achieved remarkable results:

- 45 % weight reduction of the additively manufactured part, while keeping the same robustness

- 25 % savings in production costs by reducing material usage and assembly times

- Number of parts reduced from 10 to 1

- Weight reduction of more than 4 kg across 16 door shafts installed in an A350 aircraft

The component was made from titanium on the EOS system EOS M 400-4.

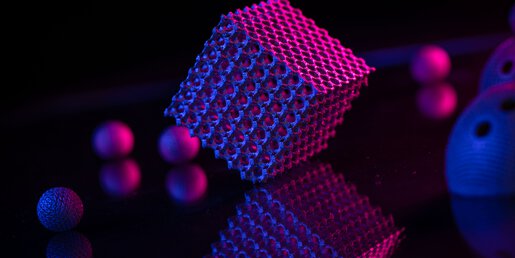

Implementing 3D Printing New Part Designs With Less Weight

Do you want to “rethink” your components?

Are you interested in implementing complex geometries, integrating functions, eliminating assembled parts and reducing weight?

Advantages of Additive Manufacturing

Lightweight parts reveal the full potential of additive manufacturing.

Other advantages of 3D printing include: bionics, functional integration, complexity and product customization.