Fewer Parts. Reduced Assembly Costs.

Improved Cost-Efficiency.

Why is it necessary to bundle functionality with as few individual components as possible?

In general, there are many applications where a compact, spatially efficient design with the same functionality is especially important. Fewer assembly parts mean lower assembly costs, a reduced likelihood of errors and more economical logistics costs. Numerous examples exist that demonstrate how tool-free additive manufacturing enabled by EOS can be used to manufacture all required parts in a single step.

Functional parts such as joints, chain links, stabilized springs or scissor mechanisms are often used in automation and production technology. Individualized and complicated devices are needed for gripping, transporting and storing, among other things. Other applications where functional integration plays a major role include medical technology and the production of orthoses and prostheses.

Our products have simply become more functional. With 3D printing, we have been able to do things that were not possible

with other manufacturing techniques.

Examples of Functional Integration

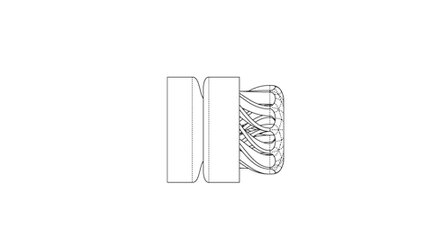

Redesign and Manufacture of a Linde HYDROPOX® Burner

Functionally Integrated With an

All-in-One Design (AiO) Using Additive Manufacturing

The Linde HYDROPOX® burner for glass surface treatment needed to be developed with as few parts as possible, lower unit costs and improved functionality.

A new type of burner was manufactured using additive manufacturing, resulting in a product that was:

- Simple: 1 component instead of 15

- Safe: welding seams were eliminated

- Efficient: homogeneous flame front

- Quick: 5 hours of construction time per burner (18 burners per job), optimized design for series production

- Increased lifespan: improved cooling channels reduce the thermal stress

- Streamlined: a more straightforward supply chain

The HYDROPOX® burner with a complex sandwich structure was manufactured on an EOS M 290 from the material EOS MaragingSteel MS1.

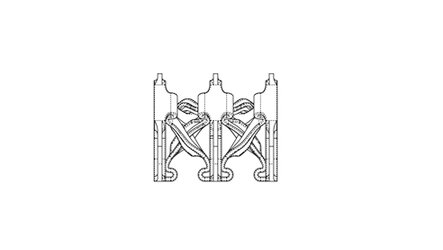

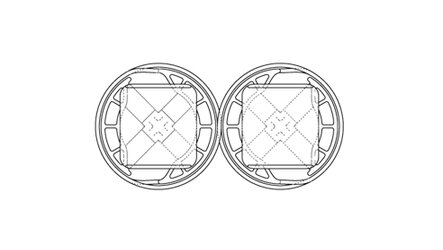

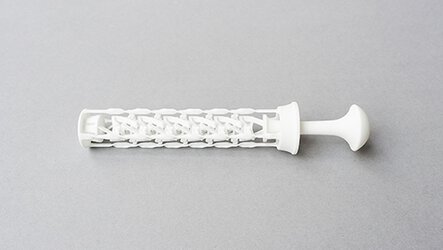

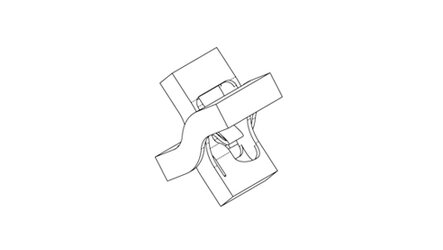

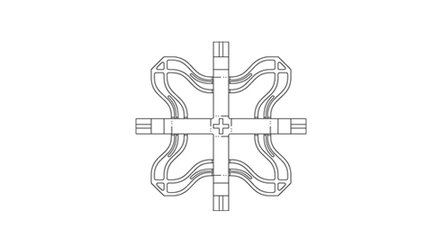

Functional Integration in Practice 3 Assembly Parts Instead of 32 – the Washing Rotor by Hettich

The centrifuge manufacturer Hettich significantly improved the cost-efficiency of its series production with additive management and by systematically exploiting the advantages of 3D printing. Typical applications of centrifuges, which use centrifugal force to separate mixtures into their components, include the preparation of blood samples or preforming blood counts. Conventionally manufactured washing rotors consist of 32 parts that need to be assembled individually. This requires complex tools and a time-consuming assembly process, especially since the stainless-steel injection tubes need to be laboriously deburred.

The transition to EOS technology proved worthwhile for Hettich - with optimal results:

- The washing rotor was redesigned and now consists of three assembly components instead of 32 – with improved functionality

- The containers are now manufactured without tools with lower production costs

- Small series productions and regional changes can be easily implemented

- Tools are no longer required for assembly, and the time-consuming deburring step is eliminated

Implementing 3D Printing Properly Using and Applying Design Freedom

Thinking in new ways is worth it: Consider how you might redevelop entire assemblies in such a way that it might be possible to produce them as a single component. The possibilities opened by the design freedom of

3D printing require a new approach.

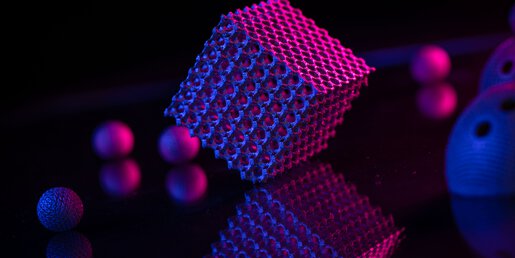

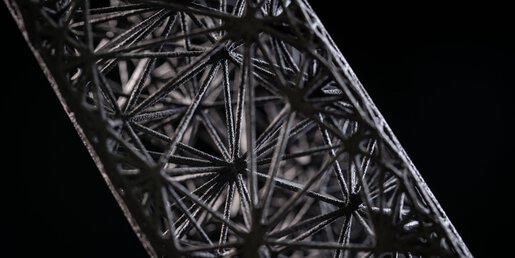

Advantages of Additive Manufacturing

Besides functional integration, the most convincing aspects of 3D printing are its great design freedom, lightweight designs, product customization and the production of complex and bionic structures.